Reading and Writing AS-i Data Bits in EcoStruxure Machine Expert - Safety

This topic contains the following information:

After having added an AS-i Gateway in EcoStruxure Machine Expert and parameterizing it in EcoStruxure Machine Expert - Safety, its data can be used in the safety-related application.

The communication between the SLC (and LMC) and the AS-i Gateway via the openSafety over Sercos is accomplished by means of the '8 Bytes Safe Sercos Data' device object you have inserted under the gateway node. This topic describes how to use the data bits contained in this device object in the safety-related application.

Data bits read from/written to the AS-i Gateway

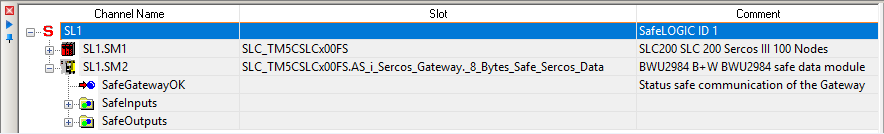

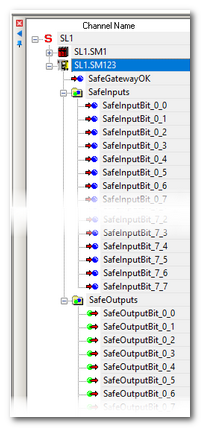

The AS-i Gateway appears as subslot of the SLC in the EcoStruxure Machine Expert - Safety devices tree ('Devices' window), similar to a bus coupler device.

Example: AS-i Gateway with device ID SL1.SM2

The data bits provided in the '8 Bytes Safe Sercos Data' device object of this particular AS-i Gateway are grouped by input and output bits under the gateway node. 64 input bits as well as 64 output bits are provided per AS-i Gateway. Additionally, the SafeGatewayOK signal is provided that indicates the communication status.

Example

The meaning of the input and output data bits and which bits are used in your application depend on the user-defined and project-specific AS-i data mapping made in your AS-i application (in ASIMON).

NOTE:

The entire bit set is transmitted to/from the AS-i Gateway, independently of the AS-i data mapping or the number/types of AS-i I/O slaves that are physically connected to the AS-i field bus. Input bits that are not used because they are not mapped to any AS-i data remain SAFEFALSE permanently. Which data bits are used and have to be read or written in the safety-related SLC application (as they are mapped to a physically connected sensor or actuator) have to be determined in the ASIMON application.

By evaluating the relevant input bits coming from the AS-i Gateway (delivering status information from AS-i sensors and command devices) and writing the output bits transferred to the AS-i Gateway (e.g., to control AS-i actuators), the safety-related SLC application can react on safety-related requests from the AS-i field bus.

The input/output bits can be inserted like any process data items into the safety-related FBD/LD code by dragging them from the devices tree (see following procedure). On insertion into the code, a safety-related global variable is created.

Additionally, each safety-related input/output bit is available as mirrored bit in EcoStruxure Machine Expert.

Mirrored bits in EcoStruxure Machine Expert

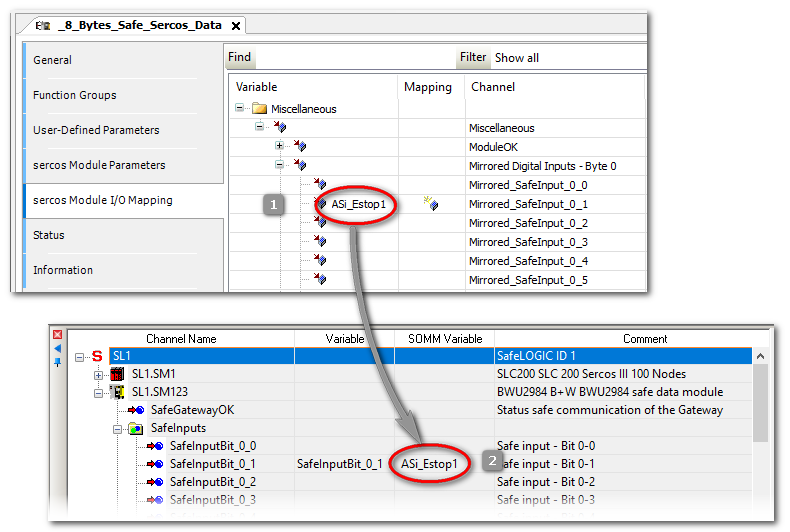

The safety-related input and output bits are mirrored in EcoStruxure Machine Expert in the 'sercos Module I/O Mapping' editor of the device object '8 Bytes Safe Sercos Data' relating to this AS-i Gateway device. After mapping an input/output bit to a Boolean variable in EcoStruxure Machine Expert, the safety-related project is updated accordingly and the name of the mapped variable is entered into the 'SOMM Variable' column in EcoStruxure Machine Expert - Safety.

Example:

EcoStruxure Machine Expert: in the 'sercos Module I/O Mapping' editor of the '8 Bytes Safe Sercos Data' device object, the variable 'ASi_Estop1' is mapped to the input bit 0.1 (number (1) in the figure below).

In EcoStruxure Machine Expert - Safety: the 'ASi_Estop1' variable is visible in the 'SOMM Variable' column in the 'Devices' window (number (2) in the figure below). In this example, input bit 0.1 is already used in the safety-related application under the variable name 'SafeInputBit_0_1'. This variable name has automatically been created when dragging the bit into the safety-related application.

Assumptions for this documentation

For the descriptions given here we assume the following:

A direct 1:1 data mapping, i.e., the address of an AS-i slave corresponds to the data bit number (input slave 1 is mapped to input bit 01, etc.).

The input bits 0 and 32 are configured as diagnostic status bits.

The output bits 0 and 32 are configured as enable output bits.

Further Information

Refer to the chapter "Configuration of the AS-i functionality in ASIMON" and to section "Description of the AS-i input/output bits" for details.

Description of the AS-i input/output bits

SafeGatewayOK status bit

|

Description |

Safety-related status bit coming from the AS-i Gateway indicating the status of the communication between the SLC and the AS-i Gateway via openSafety over Sercos. The SafeGatewayOK signal can be evaluated together with the diagnostic signals that indicate the AS-i circuit status (also delivered by the AS-i Gateway). The present documentation is predicated on the best practice application in which these diagnostic bits are mapped to the input data bits 0 (for circuit 1) and 32 (for circuit 2). Refer to section "Circuit status monitoring: input bits 0 and 32..." below for details.

Representation in the devices tree: |

|

Data type |

SAFEBOOL |

|

Access type |

Variable can be read by the safety-related SLC application. |

|

Possible values |

SAFEFALSE:

SAFETRUE:

NOTE: Also observe the status display at the AS-i Gateway for the error indication. |

Input bits 1 to 31 and 33 to 63

|

Description |

Safety-related input bit coming from the AS-i Gateway. Exceptions: the present documentation is predicated on the best practice application in which the input bits 0 and 32 are configured for monitoring the status of the AS-i circuits 1 and 2 (see section below).

Representation in the devices tree: NOTE: As we use a direct 1:1 data mapping, the bit number directly corresponds to an AS-i slave address. Refer to your project documentation of the AS-i application (made using ASIMON) for details of your AS-i data mapping. |

|

Data type |

SAFEBOOL |

|

Access type |

Variable can be read by the safety-related SLC application. |

|

Possible values |

SAFEFALSE and SAFETRUE. The meaning of the bit values SAFETRUE and SAFEFALSE depends on the AS-i data mapping and your AS-i application. As we use a direct 1:1 data mapping (AS-i slave address = bit number), the following applies: SAFEFALSE:

SAFETRUE:

NOTE: A SAFETRUE value is only valid if the SafeGatewayOK signal and the diagnostic status signal for the corresponding AS-i circuit are both SAFETRUE. The present documentation is predicated on the best practice application in which the diagnostic signal for circuit 1 is mapped to input data bit 0 and the diagnostic bit for circuit 2 is mapped to input bit 32. Refer to section "Circuit status monitoring: input bits 0 and 32..." below for details. NOTE: Also observe the status display at the AS-i Gateway for the error indication. |

Output bits 1 to 31 and 33 to 63

|

Description |

Safety-related output bit written to the AS-i Gateway. Exceptions: the present documentation is predicated on the best practice application in which the output bits 0 and 32 are configured for enabling the AS-i circuits 1 and 2 (see section below).

Representation in the devices tree: NOTE: As we use a direct 1:1 data mapping, the bit number may directly correspond to an AS-i actuator ID. Refer to your project documentation of the AS-i application (made using ASIMON) for details of your AS-i data mapping. |

|

Data type |

SAFEBOOL |

|

Access type |

Variable can be written by the safety-related SLC application. |

|

Possible values |

SAFEFALSE and SAFETRUE. The meaning of the bit values SAFETRUE and SAFEFALSE depends on the AS-i data mapping and your AS-i application. As we use a direct 1:1 data mapping (AS-i slave address = bit number), the following applies:

NOTE: The present documentation is predicated on the best practice application in which the output bits 0 and 32 are configured for enabling the AS-i circuits 1 and 2. This way, the value SAFETRUE written to an output bit can only become effective in the output process data image of the AS-i Gateway (and therefore on the addressed AS-i field bus circuit) if the related enable output signal (output bit 0 or 32) enables the respective AS-i Gateway circuit with the value SAFETRUE. Output data bit 0 controls circuit 1, output bit 32 controls circuit 2 (see section below). |

Circuit status monitoring: input bits 0 and 32 correspond to TM5/TM7 SafeModuleOK signal

If configured in ASIMON, the AS-i Gateway provides diagnostic status signals for both AS-i circuits (similar to the SafeModuleOK signal from TM5/TM7 modules). The present documentation is predicated on the best practice application in which you have implemented these diagnostic signals as follows:

The diagnostic status signals are mapped in ASIMON to the input bits 0 and 32 of the '8 Bytes Safe Sercos Data' device object. Input data bit 0 then represents the status of AS-i circuit 1, and input bit 32 represents circuit 2.

The input bits 0 and 32 are evaluated in your safety-related SLC application in a way that the signals coming from the AS-i slaves are considered as invalid if the related circuit status signal is not SAFETRUE.

NOTE:

Additionally, the SafeGatewayOK signal is available to indicate the status of the communication between SLC and AS-i Gateway via openSafety over Sercos. SafeGatewayOK = SAFEFALSE indicates that the safety-related communication via openSafety over Sercos is not established correctly.

|

Description |

Indicates the status of the respective AS-i circuit and therefore, from safety-related application perspective, the AS-i Gateway status itself. If mapped as described above, input data bit 0 represents circuit 1, and input bit 32 represents circuit 2. |

|

Data type |

SAFEBOOL |

|

Access type |

Variable can be read by the safety-related SLC application. |

|

Possible values |

SAFEFALSE: the respective AS-i circuit is not available for the SLC. The data bits contained in the '8 Bytes Safe Sercos Data' device object are not valid. SAFETRUE: the respective AS-i circuit is available for the SLC. The data bits contained in the '8 Bytes Safe Sercos Data' device object are valid. |

Circuit enabling: output bits 0 and 32 correspond to TM5/TM7 ReleaseOutput signal

The present documentation is predicated on the best practice application in which you have implemented enable output signals for the AS-i circuits as follows:

Suitable Boolean output variables generated in the safety-related SLC application are provided as enable signals for each of the output AS-i circuits.

These enable (or release) signals are mapped to the output bits 0 and 32 of the '8 Bytes Safe Sercos Data' device object.

These output bits 0 and 32 are processed in the ASIMON application using logical AND combinations in a way that a slave may only activate its output if the enable signal is SAFETRUE.

This way, the output bits 0 and 32 of the '8 Bytes Safe Sercos Data' device object can be used for enabling the circuits 1 and 2 (similar to the ReleaseOutput signal known from TM5/TM7 modules). Setting an enable bit to SAFETRUE means that the related AS-i slaves may activate their outputs.

|

Description |

If configured as described above, the output bits 0 and 32 are the release signals for the AS-i circuits. If mapped as described above, output data bit 0 controls circuit 1, and output bit 32 controls circuit 2. Setting an output bit to TRUE must not result in any hazards. Refer to the hazard message below this table. |

|

Data type |

SAFEBOOL |

|

Access type |

Variable can be written by the safety-related SLC application. |

|

Possible values |

|

WARNING

UNINTENDED EQUIPMENT OPERATION

Include in your risk analysis the impact of setting/resetting an output bit.

Use appropriate safety interlocks where personnel and/or equipment hazards exist.

Validate the overall safety-related function and thoroughly test the application.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

How to insert data bits into the safety-related code

Use the input/output bits provided under the gateway node as follows in the safety-related application in EcoStruxure Machine Expert - Safety.

Read the status information (input bits) coming from the AS-i Gateway and evaluate them in the safety-related application. It depends on the AS-i I/O mapping defined in the AS-i application (ASIMON project) to which AS-i sensor(s)/command device(s) a bit corresponds. Also evaluate the SafeGatewayOK signal in the safety-related application.

Write the control signals (output bit) transferred to the AS-i Gateway depending on the evaluated status information. It depends on the AS-i I/O mapping defined in the AS-i application (ASIMON project) to which AS-i actuator(s) a bit corresponds. The present documentation is predicated on the best practice of a 1:1 data mapping application.

WARNING

UNINTENDED EQUIPMENT OPERATION

Verify the mapping of AS-i I/O data to the '8 Bytes Safe Sercos Data' device object and the use of AS-i input/output data bits in the safety-related SLC application.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

The bits have to be inserted into FBD/LD code worksheets as follows:

|

Download of parameterization/application data to the AS-i Gateway

After having parameterized the AS-i Gateway and used the AS-i data bits in the safety-related code as described above, the related data are part of the safety-related EcoStruxure Machine Expert - Safety project which is in turn integrated in the non-safety-related EcoStruxure Machine Expert project. These data are included into the usual project download and then transferred from the LMC to the AS-i Gateway. No separate download to the AS-i Gateway is required.

The AS-i application configuration developed using ASIMON has to be commissioned separately as described in the ASIMON user documentation.

Observe the following safety notes before commissioning the system including the coupled AS-i field bus:

WARNING

UNINTENDED EQUIPMENT OPERATION

Verify the interaction between the applications programmed for the AS-i Gateway (with its connected I/O devices) and the PacDrive 3 application (LMC and SLC programs).

Verify the mapping of AS-i I/O data to the '8 Bytes Safe Sercos Data' device object and the use of AS-i input/output data bits in the safety-related SLC application.

Verify that the safety response time of the entire system includes the response times specific to the AS-i Gateway with its connected AS-i I/O slaves.

Be sure that the functional testing you perform comprises the entire system including the AS-i Gateway and I/O slaves, and corresponds to your risk analysis, and considers each possible operating mode and scenario the safety-related application should cover.

Observe the regulations given by relevant sector standards for the distributed automation system.

Use appropriate safety interlocks where personnel and/or equipment hazards exist.

Failure to follow these instructions can result in death, serious injury, or equipment damage.