Adding/Parameterizing AS-i Gateways in EcoStruxure Machine Expert

This topic describes how to add AS-i Gateway devices to the bus structure in EcoStruxure Machine Expert and parameterize them. It contains the following information:

Preparations for integrating the AS-i Gateway

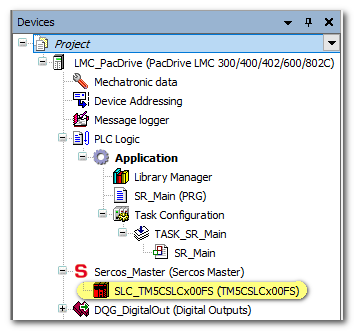

For the described integration procedure, the following should apply to your EcoStruxure Machine Expert application project:

A Safety Logic Controller is already inserted in the Devices tree.

Example:

The IP addresses of LMC and SLC are set in the respective 'Parameters' editor (section 'General' for the LMC and section 'Identification' for the SLC).

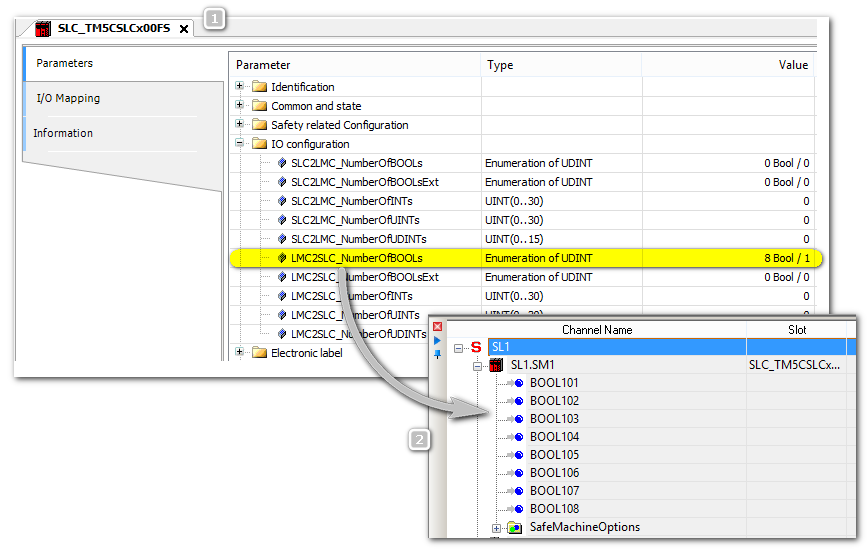

The value 'LMC2SLCNumberOfBOOLs' is set to '8 Bool / 1' in the 'IO Configuration' section of the SLC 'Parameters'. This value defines the non-safety-related communication between standard (non-safety-related) LMC controller and safety-related SLC. It defines the number of Boolean data items that are transferred between LMC and SLC. In EcoStruxure Machine Expert - Safety, each of these Boolean data items will be available as standard input signal under the SLC node in the 'Devices' window.

Example

Communication between LMC and SLC via the Sercos bus has been successfully established.

Adding an AS-i Gateway and inserting the '8 Bytes Safe Sercos Data' device object

Assuming that the preparations mentioned above are done, proceed as follows:

Add an AS-i Gateway.

In the 'Devices' tree, right-click 'SercosIII (Sercos Master)' and select 'Add Device...' from the contextual menu.

(Alternative: use 'Insert device...'. Refer to the EcoStruxure Machine Expert online help for details.)

In the 'Add Device' dialog, select 'Bihl+Wiedemann' from the 'Vendor' drop-down list.

Select the 'AS-i/Sercos III Gateway'.

(Select the correct device version. Select the 'Display all version' checkbox, if necessary.)

Click the 'Add Device' button to confirm the selection and insert the AS-i Gateway device into the 'Devices' tree.

Close the 'Add Device' dialog.

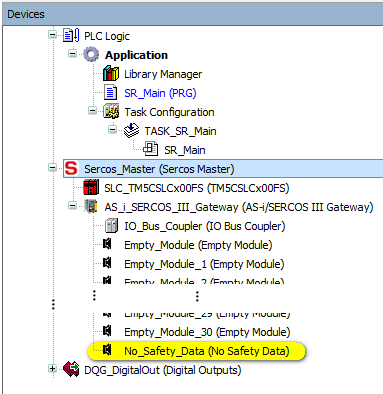

The AS-i Gateway is now visible under the Sercos_Master node in the tree like a usual Sercos bus device.

The gateway node contains:

One slot referred to as 'No_Safety_Data' into which the '8 Bytes Safe Sercos Data' device object must be inserted. This device object represents the safety-related extension of the Bihl+Wiedemann system and will be used in the PacDrive 3 system to access the input/output data bits read from/written to the AS-i Gateway. See section "AS-i/Sercos Data Exchange..." for details.

30 'EmptyModule' slots for inserting standard (non-safety-related) AS-i slaves. The 'Empty_Module' slots are not for safety-related AS-i slaves. See step 5 in this procedure.

Example:

Insert the '8 Bytes Safe Sercos Data' device object

Right-click the 'No_Safety_Data' node and select 'Plug Device...' from the contextual menu.

In the 'Plug Device' dialog, select 'Bihl+Wiedemann GmbH' from the 'Vendor' drop-down list.

Select the entry '8 Bytes Safe Sercos Data'.

(Make sure that the correct device version is selected for insertion. Select the 'Display all version' checkbox, if necessary.)

Click the 'Plug Device' button to confirm the selection and insert the device object into the 'Devices' tree.

Close the 'Plug Device' dialog.

The node is renamed to '8 Bytes Safe Sercos Data'. This device object is handled like a safety-related 64 bit I/O module, independently of what AS-i data are mapped to it.

Result of the insertion of the '8 Bytes Safe Sercos Data' device object...

... in the EcoStruxure Machine Expert - Safety project: the AS-i Gateway is integrated into the list of safety-related devices. The data bits provided by the device object are then available as safety-related input and output bits. These bits can be inserted into the safety-related application.

... in the EcoStruxure Machine Expert project: these bits are available as mirrored bits of the safety-related data bits with read-only access. They are represented as 8*8 bytes input data and 8*8 bytes output data. By mapping these mirrored bits to standard (non-safety-related) variables in the standard application, the LMC is informed about the safety-related operations of the SLC and the AS-i Gateway. See section "Mapping AS-i I/O safety-related data to standard (non-safety-related) variables (mirrored bits)" for an example.

Parameterize the AS-i Gateway device and the '8 Bytes Safe Sercos Data' device object as described in the procedure below.

In EcoStruxure Machine Expert, you can map the AS-i input/output bits (mirrored bits) to standard (non-safety-related) variables as described below.

Optional: insert standard (non-safety-related) AS-i I/O slaves or other device objects into the empty module slots. Refer to the section "Integrating standard AS-i slaves" for details.

NOTE:

Do not use the communication telegram bits of safety-related slaves in EcoStruxure Machine Expert.

According to the AS-i standard, AS-i slaves communicate using telegrams composed of 4 bits of user data. Safety-related AS-i slaves only use one data bit which is derived from the AS-i telegram (4 bits) by means of a special, device-specific algorithm. This resulting (safety-related) data bit can be mapped to the '8 Bytes Safe Sercos Data' device object and is available as mirrored bit in the standard (non-safety-related) application.

Nevertheless, all 4 bits of a safety-related slave are visible in the I/O Mapping table in EcoStruxure Machine Expert. Do not use these 4 telegram bits of safety-related AS-i slaves in the slave I/O Mapping because none of these single bits represents the derived safety-related bit mentioned above. Instead, only use the data bit of the safety-related slave which is available as mirrored bit in the '8 Bytes Safe Sercos Data' device object.

WARNING

UNINTENDED EQUIPMENT OPERATION

Do not use the 4 bits of the safety-related communication telegram for any other purposes in your application.

Failure to follow these instructions can result in death, serious injury or equipment damage.

Parameterizing the AS-i Gateways

NOTE:

Observe the notes given in section "Notes on distributed automation systems" when parameterizing the AS-i devices.

Set the Sercos parameters of the AS-i Gateway as follows:

In the EcoStruxure Machine Expert 'Devices' tree, double-click the AS-i Gateway device to be parameterized.

The editors of the device are opened in the editors area.

Click the 'Sercos III Parameters' editor.

Expand the structure in the editor grid and locate the parameters to be set.

Double-click into a 'Value' field to be edited and enter a value or, if applicable, select one after clicking the browse button '...'.

Sercos parameters of the AS-i Gateway:

Parameter section 'Identification'

|

Parameter |

Meaning |

Default |

Data type |

|

Parameter section 'Identification' |

|||

|

WorkingMode |

Sets the working mode of the device. Traceable: yes. Possible values:

|

virtual / 0 |

DINT Enumeration |

|

IdentificationMode |

Displays the identification mode, i.e., which criterion is used to automatically assign a Sercos device to an object in the LMC Configuration. Traceable: yes. Possible values:

|

TopologyAddress / 2 |

DINT Enumeration |

|

ConfiguredSercosAddress |

Displays the configured Sercos address of the device. Traceable: yes. |

100 |

UINT |

|

ConfiguredSerialNumber |

Displays the configured serial number of the device. |

(empty) |

STRING(80) |

|

IPConfigMode |

Defines whether Sercos slaves are to be configured manually or automatically. Traceable: yes. Possible values:

|

Automatic IP addressing / 0 |

DINT Enumeration |

|

IPAddress |

Specifies the IP address of the AS-i Gateway. Traceable: yes. |

172.20.0.3 |

STRING(15) |

|

Subnetmask |

Defines the subnet mask of the slave device. Can only be set if: IPConfigMode = manual IP addressing (software) / 2. Access type: read/write Traceable: no. While the value for this parameter is being entered, the parameter is verified for the following:

|

255.255.252.0 |

STRING(15) |

|

Gateway |

Defines the gateway of the slave device. Can only be set if: IPConfigMode = manual IP addressing (software) / 2. Access type: read/write Traceable: no. While the value for this parameter is being entered, the parameter is verified for the following:

During the setting of the configuration, the following is checked for this parameter:

|

172.20.0.1 |

STRING(15) |

|

Section 'Common and state' |

|||

|

ProducerCycleTime |

Displays the cycle time in ns at which the cyclic data of a Sercos device are compared to the terminal. This parameter is taken over during Sercos start-up. This parameter must be an integer multiple of the Sercos cycle time for Sercos I/O devices. Example: ProducerCycleTime = 1000000 ns Sercos III.CycleTime = 4000000 ns Used ProducerCycleTime during start-up: 4000000 ns No diagnostic message is triggered. If a value which is not supported by the Sercos device is entered, error 8508 "Sercos run-up not possible" occurs with the ExtDiagMsg "C_Time=20000" |

1000000 [ns] |

DINT |

|

Section 'System internals' |

|||

|

System internals are parameters that are reserved and must not be used by the application or accessed during configuration. |

|||

WARNING

UNINTENDED EQUIPMENT OPERATION

Do not use nor modify System internal parameters.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

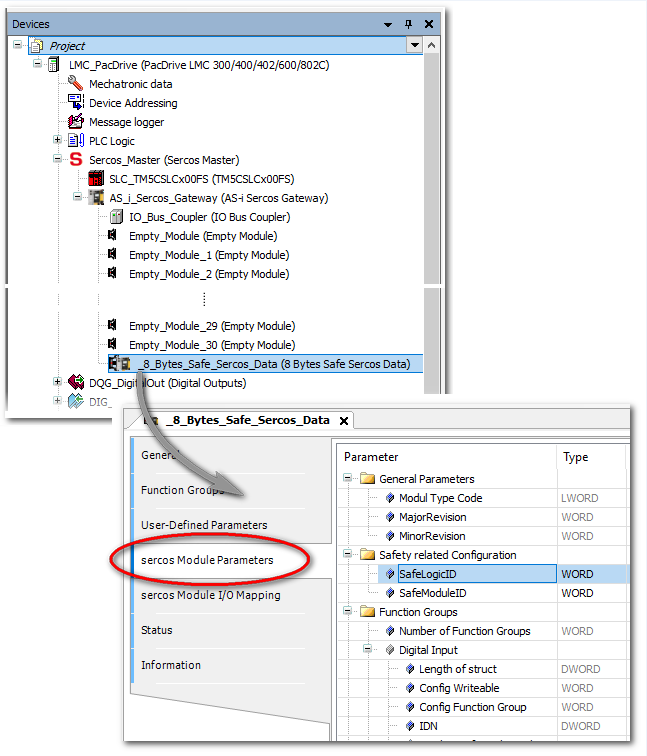

Then, parameterize the device object '8 Bytes Safe Sercos Data' as follows:

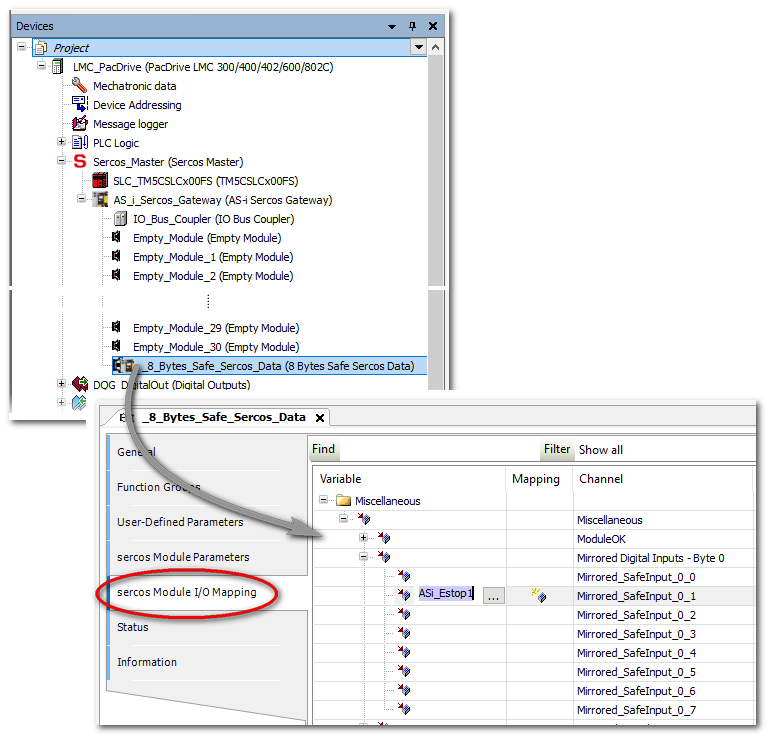

In the EcoStruxure Machine Expert 'Devices' tree, double-click the '8 Bytes Safe Sercos Data' device object.

The editors of the device are opened in the editors area.

Click the 'Sercos Module I/O Mapping' editor.

Expand the byte structure in the editor grid and locate the mirrored bit to be mapped.

Double-click into the grid field (in the 'Mapping' column) and enter a variable name or select an already declared variable with the browse button '...'.

Sercos parameters of the '8 Bytes Safe Sercos Data' device object:

Both parameters are located in the 'Safety-related Configuration' section.

|

Parameter |

Meaning |

Default |

Data type |

|

SafeLogicID |

Unique number of the SLC (Safety Logic Controller) |

1 |

WORD |

|

SafeModuleID |

Unique number of the safety-related module |

2 |

WORD |

Example: parameterization of the device object '8 Bytes Safe Sercos Data'

Mapping AS-i I/O safety-related data to standard (non-safety-related) variables (mirrored bits)

After having inserted the '8 Bytes Safe Sercos Data' device object, mirrored bits of the safety-related data bits are available in the standard (non-safety-related) application. By mapping these mirrored bits to standard variables in the standard application in EcoStruxure Machine Expert, the LMC is informed about the safety-related operations of the SLC and the AS-i Gateway. In EcoStruxure Machine Expert, these mirrored bits of AS-i data are organized as 8*8 bytes input data and 8*8 bytes output data (unlike to the representation in EcoStruxure Machine Expert - Safety, where the bits are grouped as input and output bits).

Proceed as follows:

In the EcoStruxure Machine Expert 'Devices' tree, double-click the '8 Bytes Safe Sercos Data' device object.

The editors of the device are opened in the editors area.

Click the 'sercos Module I/O Mapping' editor.

Expand the byte structure in the editor grid and locate the mirrored bit to be mapped.

Double-click into the grid field (in the 'Mapping' column) and enter a variable name or select an already declared variable with the browse button '...'.

Example

Further Information

Further information on mapping I/O data can be found in the EcoStruxure Machine Expert online help.

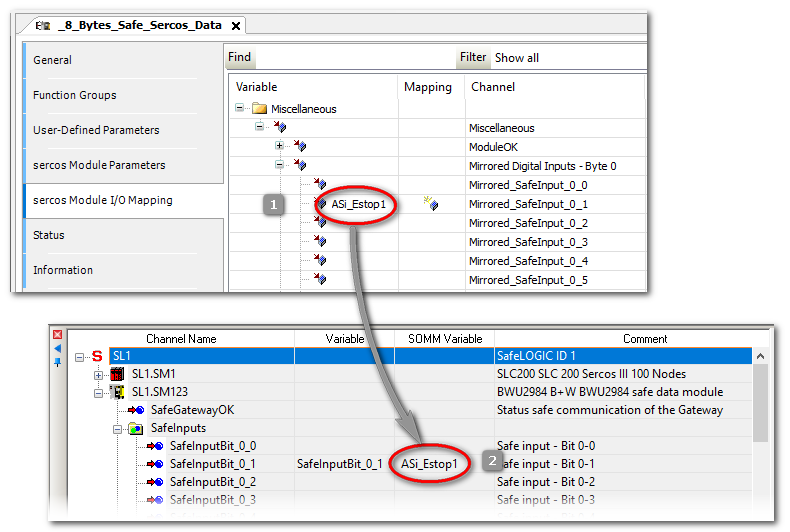

After mapping an input/output bit to a Boolean variable in EcoStruxure Machine Expert, the safety-related project is updated accordingly by entering the name of the mapped variable in the column 'SOMM Variable' in EcoStruxure Machine Expert - Safety. See topic "Evaluating and Writing to AS-i I/O Devices in EcoStruxure Machine Expert - Safety".

Example

EcoStruxure Machine Expert: in the 'sercos Module I/O Mapping' editor of the '8 Bytes Safe Sercos Data' device object, the variable 'ASi_Estop1' is mapped to the input bit 0.1 (number (1) in the figure below).

In EcoStruxure Machine Expert - Safety: the 'ASi_Estop1' variable is visible in the 'SOMM Variable' column in the 'Devices' window (number (2) in the figure below). In this example, input bit 0.1 is already used in the safety-related application under the variable name 'SafeInputBit_0_1'. This variable name has automatically been created when dragging the bit into the safety-related application.

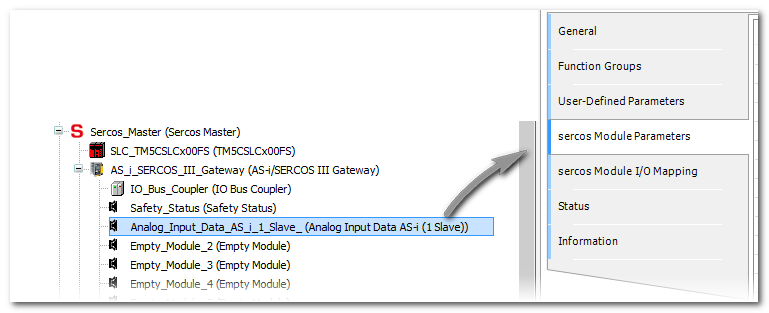

Optional: integrating standard AS-i slaves

Standard (non-safety-related) slaves connected to the AS-i field bus can be inserted into the 'EmptyModule' slots under the AS-i Gateway. This way, their process data can be accessed in the non-safety-related LMC application. These standard slots/devices are not relevant for the safety-related aspect covered by this documentation. Therefore, their use is not part of this documentation.

To insert standard slaves into the empty modules slot, proceed in the same way as for inserting the safety-related device object. See section "Adding an AS-i Gateway and inserting the '8 Bytes Safe Sercos Data' device object" for details.

To parameterize an inserted standard AS-i slave, double-click its tree node in the 'Devices' tree and select the desired editor.

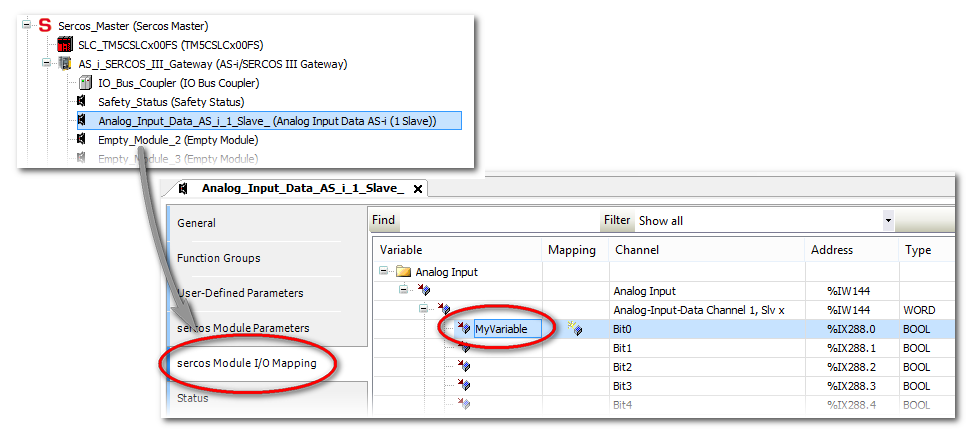

To map the I/O data of a standard AS-i slave:

In the EcoStruxure Machine Expert 'Devices' tree, double-click the slave to edited. The editors of the device are opened in the editors area.

Click the 'sercos Module I/O Mapping' editor.

Expand the data structure in the editor grid and locate the signal to be mapped.

Double-click into the grid field (in the 'Mapping' column) and enter a variable name or select an already declared variable with the browse button '...'.

Further Information

Refer to the EcoStruxure Machine Expert online help for details how to insert, parameterize, and use standard I/O devices. Information on the AS-i standard I/O slaves can be found in the related documentation provided by Bihl+Wiedemann.

NOTE:

If standard AS-i slaves are inserted into the 'EmptyModule' slots under the gateway node, this does not reduce the size of the '8 Bytes Safe Sercos Data' device object. This device object has always the length of 64 bits, independently of the number of bits which are used by safety-related slaves. However, after connecting standard slaves to the AS-i bus, some of the 64 safety-related data bits in the device object may be unused. Refer to the project documentation of your AS-i application (ASIMON project) to determine which safety-related data bits are actually used.

Download of parameterization data to the AS-i Gateway

After having inserted and parameterized the AS-i Gateway as described above, the related data are part of the EcoStruxure Machine Expert project. Therefore, they are included into the usual project download and then transferred from the LMC to the AS-i Gateway; no separate download to the AS-i Gateway is required.

The AS-i application configuration developed using ASIMON has to be commissioned separately as described in the ASIMON user documentation.

Observe the following safety notes before commissioning the system including the coupled AS-i field bus:

WARNING

UNINTENDED EQUIPMENT OPERATION

Verify the interaction between the applications programmed for the AS-i Gateway (with its connected I/O devices) and the PacDrive 3 application (LMC and SLC programs).

Verify the mapping of AS-i I/O data to the '8 Bytes Safe Sercos Data' device object and the use of AS-i input/output data bits in the safety-related SLC application.

Verify that the safety response time of the entire system includes the response times specific to the AS-i Gateway with its connected AS-i I/O slaves.

Be sure that the functional testing you perform comprises the entire system including the AS-i Gateway and I/O slaves, and corresponds to your risk analysis, and considers each possible operating mode and scenario the safety-related application should cover.

Observe the regulations given by relevant sector standards for the distributed automation system.

Use appropriate safety interlocks where personnel and/or equipment hazards exist.

Failure to follow these instructions can result in death, serious injury, or equipment damage.