SDIneg and SDIpos - Safe Direction Negative/Positive function

General function description

The Safe Direction safety-related function ensures that rotation/movement is only possible in the permitted (parameterized) direction.

The function block distinguishes two rotation/movement directions by providing separate inputs for requesting the SDI Negative or SDI Positive monitoring function: SDIneg and SDIpos. Both SDI monitoring functions are configured using the same parameters but can be requested independent of each other.

NOTE:

In which physical rotation/movement direction SDIpos or SDIneg actually results, depends on your application.

NOTE:

If SDIpos and SDIneg are requested at the same time, the SS1 function is automatically executed as the defined fallback function.

The SDIneg/SDIpos function prevents the motor from rotating more than a defined amount into the incorrect direction (device parameter SDI_PositionTolerance[sTol], see below).

Monitoring by the safety-related FB/Safety Module

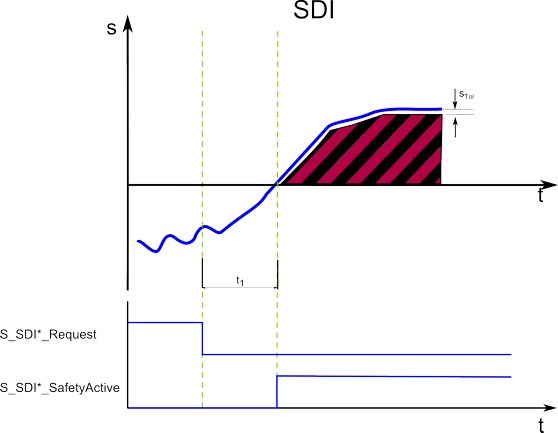

The request of the safety-related function occurs at the beginning of the t1 time interval ('S_SDI*_Request' signal in the diagram). t1 is set with the device parameter SDI_StartDelayTime[t1].

Within the t1 time interval, the standard (non-safety-related) controller also receives the request from the connected process and initiates the motion control function according to the logic and drive parameterization defined in the standard (non-safety-related) application.

After t1 has elapsed, the direction is monitored by capturing the actual position. Moving/rotating a certain distance against the allowed direction is permitted if it does not exceed the defined position tolerance STol.

If the SDI function is executed successfully, the function block switches S_SDI*_SafetyActive = SAFETRUE (see diagram).

If the SS1 fallback function has been activated due to an error detected of the position tolerance as described below, this is indicated by S_SS1_SafetyActive = SAFETRUE.

Fallback function

If the actual position moves more than the set position tolerance (parameter SDI_PositionTolerance[sTol]) into the wrong direction, the SS1 function is automatically executed as the fallback function.

Application

The SDI function is used to ensure that rotation or movement is not possible towards a prohibited direction, e.g., when personnel accesses the zone of operation of a machine.

Relevant Safety Module device parameters

How to edit the relevant safety-related device parameters: In the EcoStruxure Machine Expert - Safety 'Devices' window, ...

Left-click the Safety Module in the devices tree.

In the Device Parameterization editor on the right, scroll to the relevant parameter section (see table heading below).

Specify the parameters listed in the table below for this safety-related function.

NOTE:

For the most part, the parameters entered here are monitoring parameters. They define the monitoring behavior and thus determine if a safety-related function is executed as defined or if a fallback function is to be executed due to error detection. The actual drive parameterization (such as deceleration parameters, etc.) is defined by you in EcoStruxure Machine Expert. See topic "Functional description".

The parameters listed in the following table are used to configure both the SDIneg and SDIpos functions. Although they are parameterized identically, they can be requested independent of each other.

For detailed information on the value ranges and default values for these parameters, refer to the corresponding chapter for the safety module used in the "Safety Module Parameters and Process Data Items" guide.

|

Parameter section: Safe_Direction |

|

|

SDI_StartDelayTime[t1] |

Delay time after which the monitoring of the safety-related function is started. This value must correspond to the time period, the entire motion control system needs to react, i.e., the time after which the standard (non-safety-related) controller is able to initiate the requested safety-related function after receiving the request coded as process data control word via the SERCOS bus. This interval is referred to as t1 in the timing diagram shown above. The value set here must be equal or greater than the entire system response time including the standard system response time. The value must not be smaller than the shortest possible total response time of the involved components, i.e., the earliest point in time, when the drive is able to decelerate. |

|

SDI_PositionTolerance[sTol] |

Allowed deviation from the monitored position to determine the direction (STol in the figure above). If the deviation exceeds the defined value after t1 has elapsed, the SS1 function is activated as the defined fallback function. |

WARNING

NON-CONFORMANCE TO SAFETY FUNCTION REQUIREMENTS

Validate that the executed rotation/movement direction of the machine (negative/positive) and the selected safety-related function (SDIneg/SDIpos) fit together in your application.

Be sure that your risk analysis includes an evaluation for setting incorrectly the rotations/movements.

Use appropriate safety interlocks where personnel and/or equipment hazards exist.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

WARNING

NON-CONFORMANCE TO SAFETY FUNCTION REQUIREMENTS

Verify that the device parameters for the Safety Module correspond to your risk analysis.

Be sure that your risk analysis includes an evaluation for setting incorrectly device parameter values.

Validate the overall safety-related function with regard to the set device parameter values and thoroughly test the application.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Relevant FB inputs/outputs and bits in status word

Function monitoring request via FB inputs S_SDIpos_Request = SAFEFALSE and S_SDIneg_Request = SAFEFALSE

Function status indication via FB outputs S_SDIpos_SafetyActive and S_SDIneg_SafetyActive (SAFETRUE = safety-related function activated)

In the DWORD output at AxisStatus

bit 13: SDIpos (TRUE = safety-related function activated)

bit 14: SDIneg (TRUE = safety-related function activated)