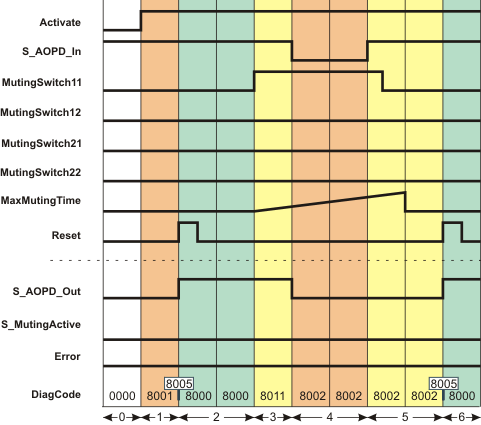

Additional signal sequence diagram

Temporary intermediate states are not illustrated in the signal sequence diagram. Only typical input signal combinations are illustrated in this diagram. Other signal combinations are possible.

The most significant areas within the signal sequence diagram are highlighted in color.

Further Information

The diagram in the overview for this function block must also be taken into account.

NOTE:

The signal sequence diagrams in this documentation possibly omit particular diagnostic codes. For example, a diagnostic code is possibly not shown if the related function block state is a temporary transition state and only active for one cycle of the Safety Logic Controller.

Only typical input signal combinations are illustrated. Other signal combinations are possible.

NOTE:

Only the material flow direction from muting sensors MutingSwitch11 MutingSwitch12 to muting sensors MutingSwitch21

MutingSwitch12 to muting sensors MutingSwitch21 MutingSwitch22 is described in the following. This means the sequential muting sensor pair MutingSwitch11/MutingSwitch12 is positioned before the safety-related equipment and MutingSwitch21/MutingSwitch22 is behind the safety-related equipment. This is illustrated in the graphic in the function block overview.

MutingSwitch22 is described in the following. This means the sequential muting sensor pair MutingSwitch11/MutingSwitch12 is positioned before the safety-related equipment and MutingSwitch21/MutingSwitch22 is behind the safety-related equipment. This is illustrated in the graphic in the function block overview.

The function block also supports the opposite material flow direction from muting sensors MutingSwitch22 MutingSwitch21 to muting sensors MutingSwitch12

MutingSwitch21 to muting sensors MutingSwitch12 MutingSwitch11. The functional sequence remains identical.

MutingSwitch11. The functional sequence remains identical.

Object in zone of operation, muting inactive, stop request via safety-related equipment, start-up inhibit active

The signal sequence diagram shown below indicates what happens if an object (e.g., a rod) interrupts the light beam of the first muting sensor located before the safety-related equipment (see situation (1)) and then moves forward to enter the zone of operation of the protected machine, i.e., also interrupts the light beam of the safety-related equipment (see situation (2)). This triggers a stop request because muting is not active. To activate muting for the material flow direction mentioned, the muting sensors at the inputs MutingSwitch11 and MutingSwitch12 must switch to TRUE in the correct sequence, i.e., MutingSwitch11 must first detect the object and then MutingSwitch12, i.e., switch to TRUE.

MS_11, MS_12: First sequential muting sensor pair, connected to function block inputs MutingSwitch11 and MutingSwitch12 (the "yellow light beams" symbolize the detection area)

MS_21, MS_22: Second sequential muting sensor pair, connected to function block inputs MutingSwitch21 and MutingSwitch22

Additional assumptions:

S_StartReset = SAFEFALSE: Start-up inhibit after the function block has been activated and after the Safety Logic Controller has started up.

MutingEnable = TRUE (constant): No separate enable signal required for the muting operation.

|

0 |

The function block is not yet activated (Activate = FALSE). As a result, all outputs are FALSE or SAFEFALSE. |

|

1 |

After the function block has been activated by Activate = TRUE, the start-up inhibit is active at first. Therefore, the S_AOPD_Out enable output remains SAFEFALSE. |

|

2 |

A positive signal edge at the Reset input resets the start-up inhibit. The S_AOPD_Out output becomes SAFETRUE immediately because

|

|

3 |

The object in our example interrupts the light beam of the muting sensor at the MutingSwitch11 input, thus switching the signal to TRUE (situation (1) in the graphic above). The time measurement for the overall muting duration set at MaxMutingTime starts after this state change at MutingSwitch11. |

|

4 |

Before muting can be activated (for which the signal at the MutingSwitch12 input must also switch to TRUE), the rod also interrupts the light grid of the safety-related equipment (situation (2) in the graphic above), i.e., S_AOPD_In switches to SAFEFALSE. When S_AOPD_In switches to SAFEFALSE, the muting operation is canceled. As a result, the enable output S_AOPD_Out is switched to SAFEFALSE. |

|

5 |

The rod has been removed from the detection area of the safety-related equipment and the muting sensor. This switches S_AOPD_In to SAFETRUE and MutingSwitch11 to FALSE again. Although the light beams of all sensors are no longer interrupted, the S_AOPD_Out enable output remains SAFEFALSE, as a positive edge is first expected at the Reset input. |

|

6 |

A positive signal edge at the Reset input resets the start-up inhibit. As S_AOPD_In = SAFETRUE (light beam of the safety-related equipment is not interrupted), the S_AOPD_Out output switches to SAFETRUE. |