Group activation of safety equipment

Group activation/deactivation of safety equipment refers to the possibility of manually connecting and disconnecting different, mutually independent safety-related functions via a common signal. This equipment cannot be operated when disconnected.

WARNING

UNINTENDED START-UP

Be sure that your risk analysis includes an evaluation for the deactivation of safety equipment.

Make certain that appropriate procedures and measures (according to applicable sector standards) have been established when deactivating safety equipment.

Use appropriate safety interlocks where personnel and/or equipment hazards exist.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Single-channel application

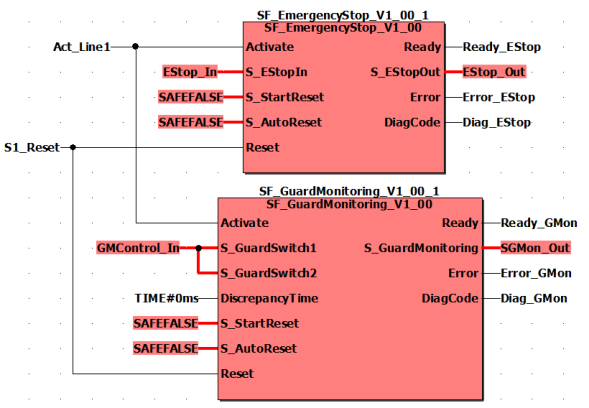

The graphic below shows a code example for this type of group deactivation in a single-channel layout.

In this example, different items of safety equipment, which are evaluated by different safety-related function blocks, act on different safety-related outputs of the Safety Logic Controller: For the function block SF_EmergencyStop on output S_EStop_Out (global I/O variable EStop_Out) and for SF_GuardMonitoring on output S_GuardMonitoring (global I/O variable SGMon_Out). These outputs control different, mutually independent safety-related functions.

The safety-related function blocks are activated or deactivated (with the Activate input) via the same signal. When a function block is deactivated (with the Activate input), all mutually dependent safety-related functions are disconnected.

Two-channel application

If the risk analysis shows that the safety equipment needs to be implemented on a two-channel basis, the example shown above must be implemented with two-channel input/output signals.