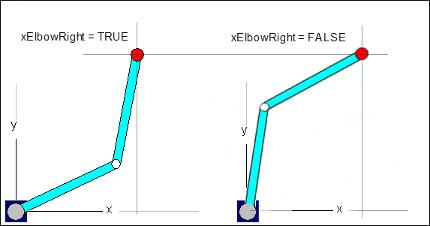

A kinematic configuration describes the layout of the axes in an axis group to one another. Depending on the kinematics, multiple configurations are possible at the same TCP position.

For example, two possible configurations are shown for SCARA 2.

The axis group has an active configuration that does not necessarily have to correspond to the current axis positions. If a movement is commanded, then the target position may be converted into axis coordinates The configuration that is active at the time of commanding is used.

This active configuration can be set with the function block SMC_SetKinConfiguration. During initialization and each time the kinematics are changed, the axis group applies the standard configuration. All kinematics with a configuration has a standard configuration.

Note

A CP movement between two configurations is not possible. In this case, the positioning has to be done by means of a PTP movement.

Note

The current configuration can be determined with the function block MC_GroupReadActualPosition.

Setting the configuration for one kinematic design

Every kinematic design with a configuration has its own POU for calculating the configuration data. The name of this function block corresponds to the name of the kinematic design plus the postfix _config. The POU converts the different configurations into the data type ConfigData. This data type is passed to the function block SMC_SetKinConfiguration.

Example: Setting a configuration for a SCARA 2 kinematic design

Call the function block Kin_Scara2_Z_Config from the library SM3_Transformation. Input xElbowRight = TRUE

⇒ The function block yields the configuration data of type ConfigData.

Call the function block SMC_SetKinConfiguration from the library SM3_Robotics. Write the input ConfigData with the previously determined configuration data.

⇒ Set the active configuration of the SCARA 2.

VAR

config: TRAFO.Kin_Scara2_Z_Config;

skc: SMC_SetKinConfiguration;

END_VAR

config(xElbowRight := TRUE);

skc(AxisGroup := Scara2, Execute := TRUE, ConfigData := config.Config);

Handling of coupled kinematics

Coupled kinematics exist when positioning kinematics and tool kinematics are used at the same time. This results in the coupled configuration from both configurations by calling Kin_Coupled_Config from the library SM3_Transformation. In this case, the configuration of the positioning kinematics and the tool kinematics is provided to the function block at the inputs.