CNC Example 2: Online Decoding with Variables

Refer to the CNConline.project sample project in the installation directory of CODESYS.

Creating an NC program in the CNC editor

Create a CNCOnline program with a SoftMotion controller.

Create a global variable list and declare two variables.

VAR_GLOBAL

g_x: REAL:=100;

g_y:REAL:=50;

END_VAR

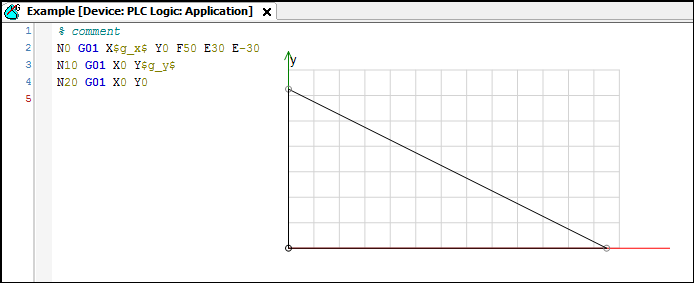

Insert a CNC program object named Example.

Select the Implementation Din66025 and the Compile mode SMC_CNC_REF. This mode is required because you use variables in your program.

Specify the following motion blocks:

Creating a drive interface and PLC configuration

Define a drive structure (e.g. CNCdirect).

See also

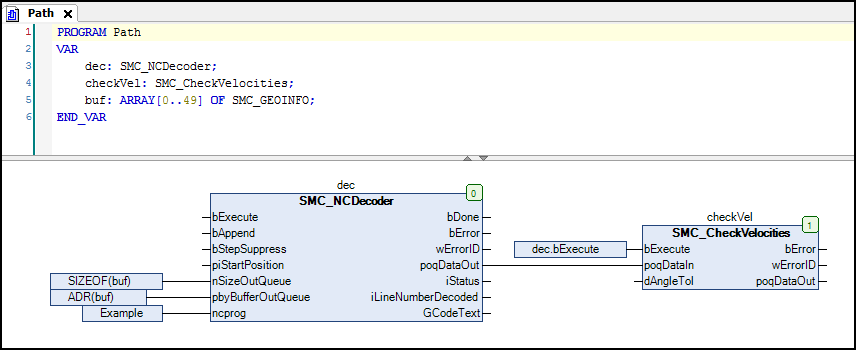

Add a POU (CFC) named Path to the application.

The decoding of the NC program for OUTQUEUE and the velocity check take place in the Path program.

Calling SMC_CheckVelocities is mandatory.

Add a POU (CFC) named Ipo to the application.

This program is almost identical to the sample project CNCdirect. However, the data input of the interpolator does not correspond to the CNC program names (ADR(Example)), but to the OutQueue output of the path preprocessing function blocks (checkVel.poqDataOut).

See also

Creating a task for path preprocessing

Because you have selected the compile mode SMC_CNC_REF, you must perform decoding and path preprocessing in the IEC program. This calculation is time consuming. It must not be executed in the interpolator cycle because one path object is generated per decoder call, and this object is typically used for many interpolator calls. You should relocate this operation to a task with low priority and less frequent calls.

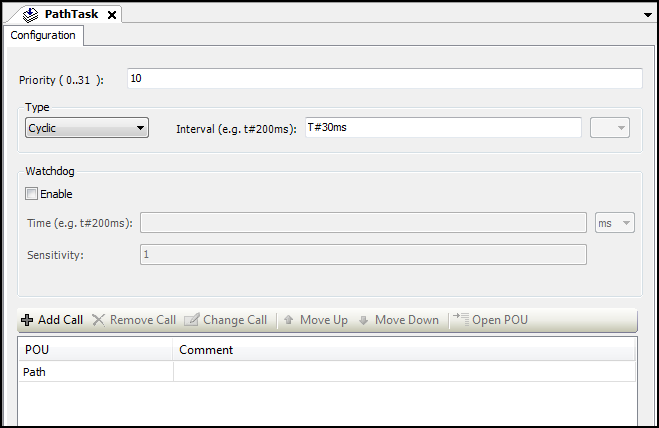

Create a PathTask task.

Priority: 10

Interval: T#30ms

Add the Path POU to the task.

Task PathTask

Underlying mechanism:

In the slow task, approximately one GEOINFO object is generated per cycle at first. This object is stored in the OUTQUEUE structure of the decoder function block. If the OUTQUEUE is full, then the function blocks of the slow task pause until the OUTQUEUE is not full anymore. This happens as soon as the fast task processes the first GEOINFO object and deletes it from the OUTQUEUE.

Then the function blocks of the slow task become active again and fill the OUTQUEUE structure.

In the fast task, a path point from the OUTQUEUE structure, which the DataIn input points to, is calculated and processed in each cycle. Because a GEOINFO object generally consists of multiple path points, it takes a few cycles until the first GEOINFO object is processed and deleted automatically by the interpolator.

As the processing of a GEOINFO object lasts several cycles as opposed to it creation, the slow task can be called less frequently than the fast task.

However, the task times must be selected so that enough GEOINFO objects are always stored in the last OUTQUEUE of the slow task, thus preventing the occurrence of any data underrun. This happens when there are no more GEOINFO objects available to the interpolator from DataIn, and the path end has not been reached yet. In this case, the interpolator slows down and stops until new data elements are available again.

Creating an operating interface and a testing interface

The visualization corresponds to the sample project CNCdirect.project. Add additional templates to the new function blocks (SMC_NCDecoder and SMC_CheckVelocities). Create a display also for the global variables g_x and g_y so that you can check their function later when commissioning.

Compile and start the created program. The program executes the CNC motion as soon as the Execute input of the decoder and interpolator has been set. If you change the values of the global variables, then they are used when the decoder is restarted and the path is adapted accordingly. Monitor the function of the Append input of the decoder as well.