Mounting the Payload to the Rotational Modules

Mounting the Gripper to the Rotational Modules

|

Step |

Action |

|---|---|

|

1 |

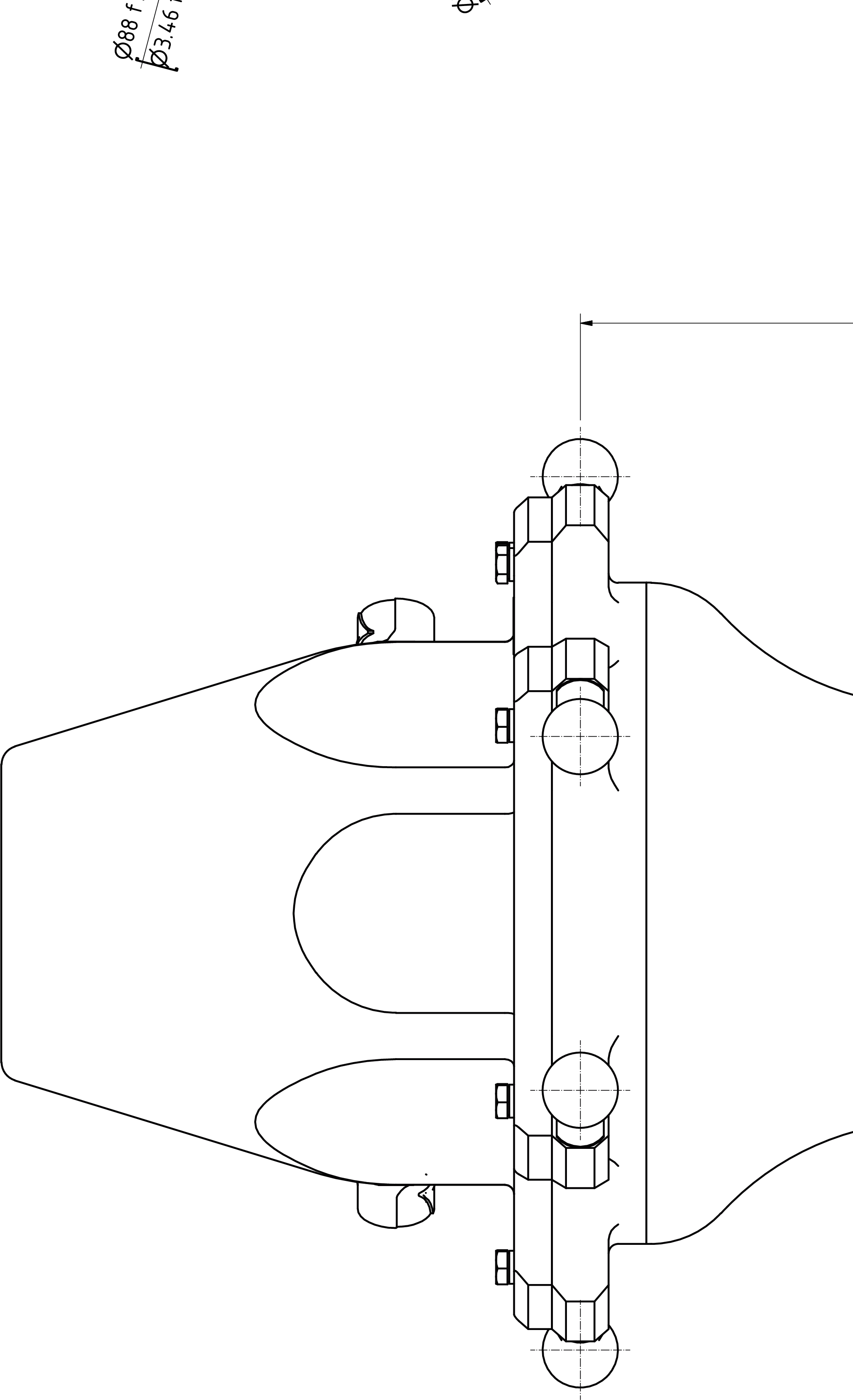

Fasten the gripper to the mounting points at the rotating flange (1) or on the fixed flange (3):

For further information, refer to Flange Dimensions for the Rotational Modules.

|

|

2 |

Calibrate the Rotational Module if this has not been done before mounting the gripper. For further information, refer to Calibrating the Double Rotational Module and the Rotational Tilting Module.

NOTE:

|

Supply of the Gripper on the Rotational Modules

|

Step |

Action |

|---|---|

|

1 |

Connect the media line to one of the pneumatic plug-in connections (1.1 or 2.1) of the Rotational Module. The plug-in connection has a diameter of 4 mm (0.0157 in).

For further information, refer to Supply of the Gripper. |

|

2 |

Connect the media line of the gripper to one of the associated connections (1.2 or 2.2) on the rotational flange of the Rotational Module. Straight fitting diameter: 4 mm (0.157 in)

NOTE:

|