Mounting The Motor

General

Electrostatic discharge to the shaft may cause incorrect operation of the encoder system and result in unanticipated motor movements and damage to the bearing.

| WARNING | |

|---|---|

If the permissible environmental conditions are not respected, external substances from the environment may penetrate the product and cause unintended movement or equipment damage.

| WARNING | |

|---|---|

The metal surfaces of the product may exceed 70 °C (158 °F) during operation.

| WARNING | |

|---|---|

Mounting

When the motor is mounted to the mounting surface, it must be accurately aligned axially and radially and make even contact with the mounting surface. All mounting screws must be tightened with the specified tightening torque. No uneven mechanical load must be applied when the mounting screws are tightened. See section Technical Data for data, dimensions and degrees of protection (IP).

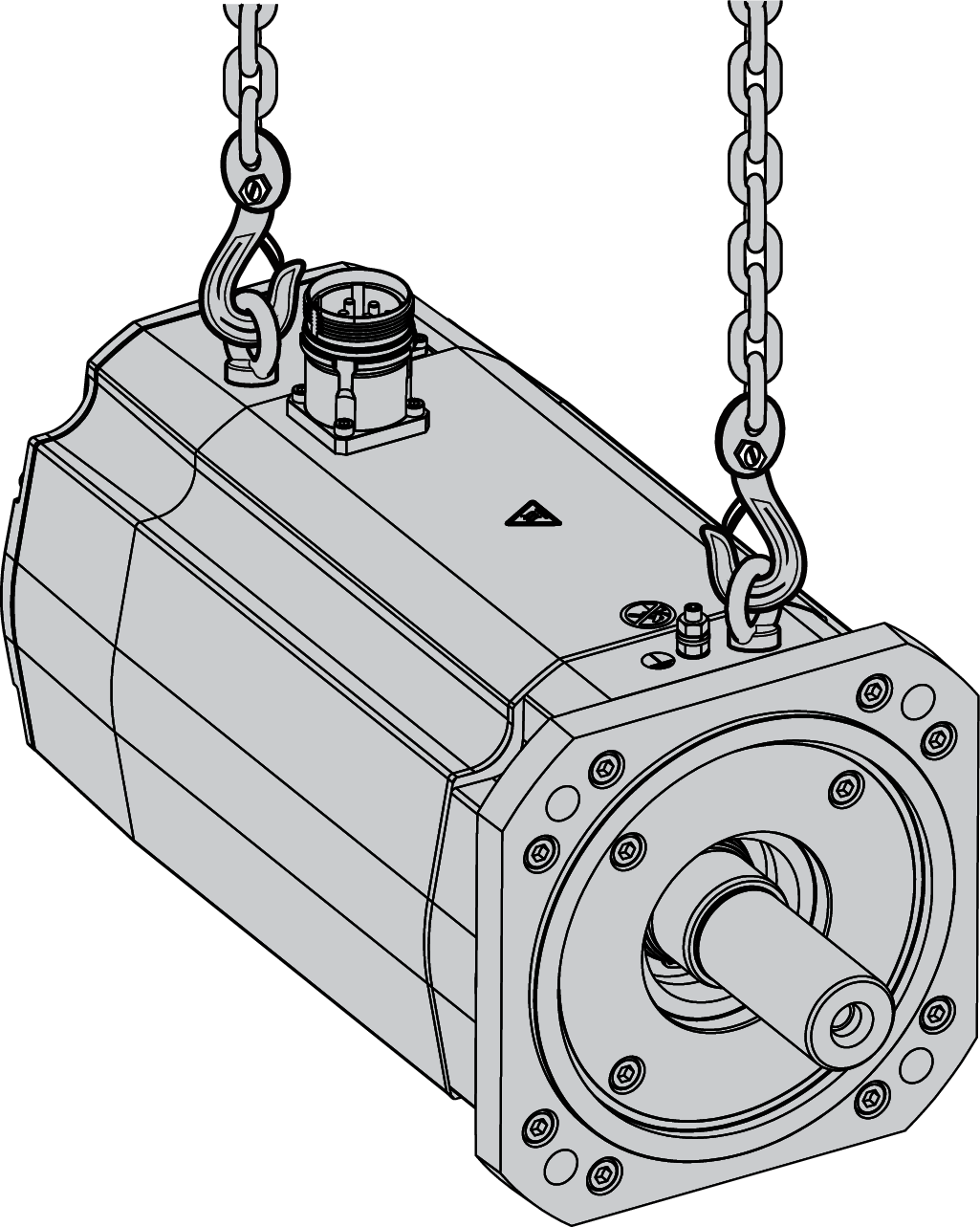

Eyebolts (SH3205 only)

The motors are equipped with eyebolts. Use the eyebolts to lift and mount the motor.

After the motor is mounted the eyebolts can be kept or removed. Remove the eyebolts if necessary, for example for rotating the connector.

Mounting Output Components

Output components such as pulleys and couplings must be mounted with suitable equipment and tools. Motor and output component must be accurately aligned both axially and radially. If the motor and the output component are not accurately aligned, this will cause runout and premature wear.

The maximum axial and radial forces acting on the shaft must not exceed the maximum shaft load values specified, see Shaft-specific Data.

If the maximum permissible forces at the motor shaft are exceeded, this will result in premature wear of the bearing or shaft breakage.

| WARNING | |

|---|---|