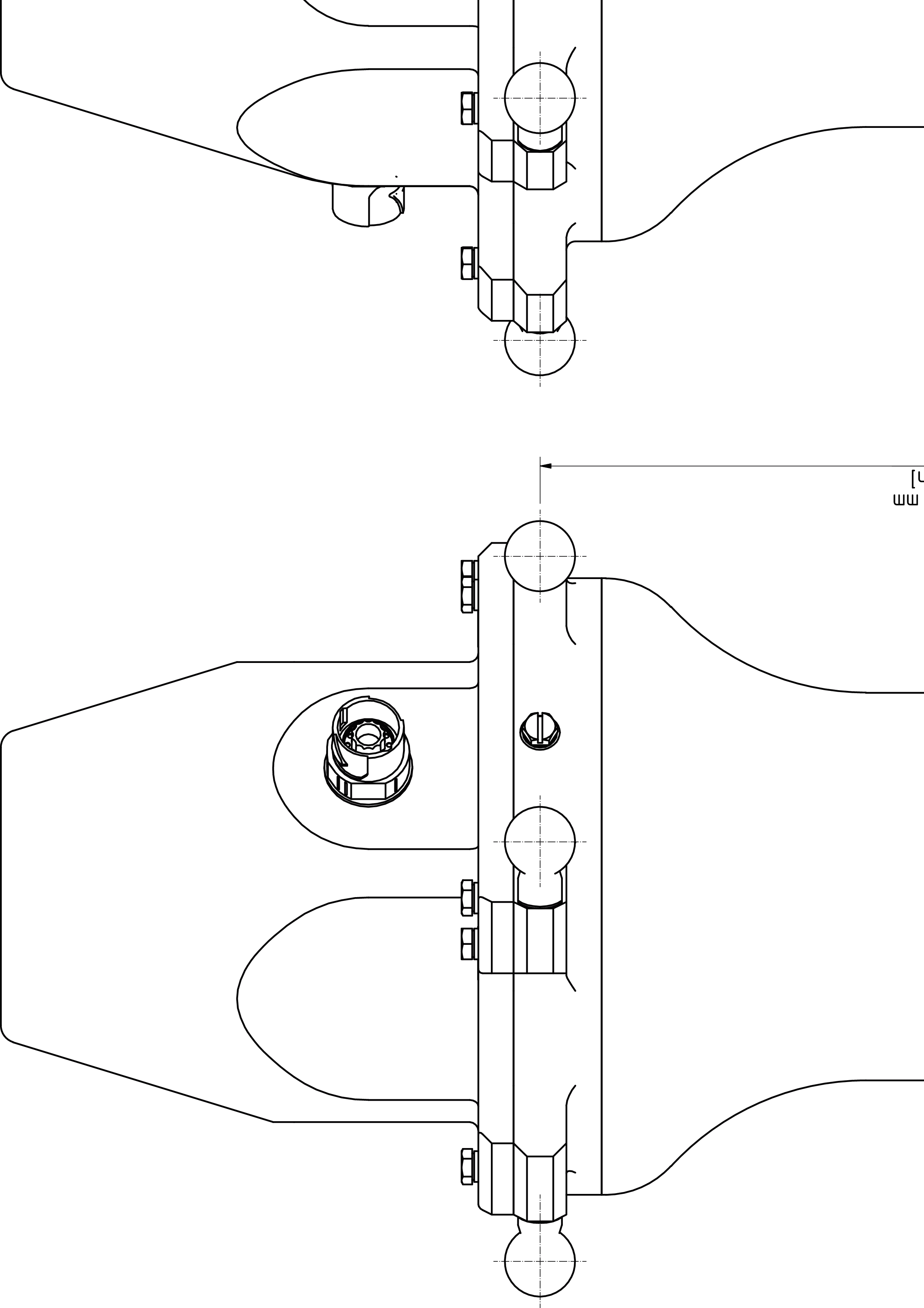

Mounting the Payload to the Tilting Modules

Mounting the Gripper to the Tilting Module B

|

Step |

Action |

|---|---|

|

1 |

Fasten the gripper to the mounting points at the flange (1):

For further information, refer to Flange Dimensions for the Tilting Module B.

|

|

2 |

Calibrate the Tilting Module B if this has not been done before mounting the gripper. For further information, refer to Calibrating the Tilting Module.

NOTE:

|

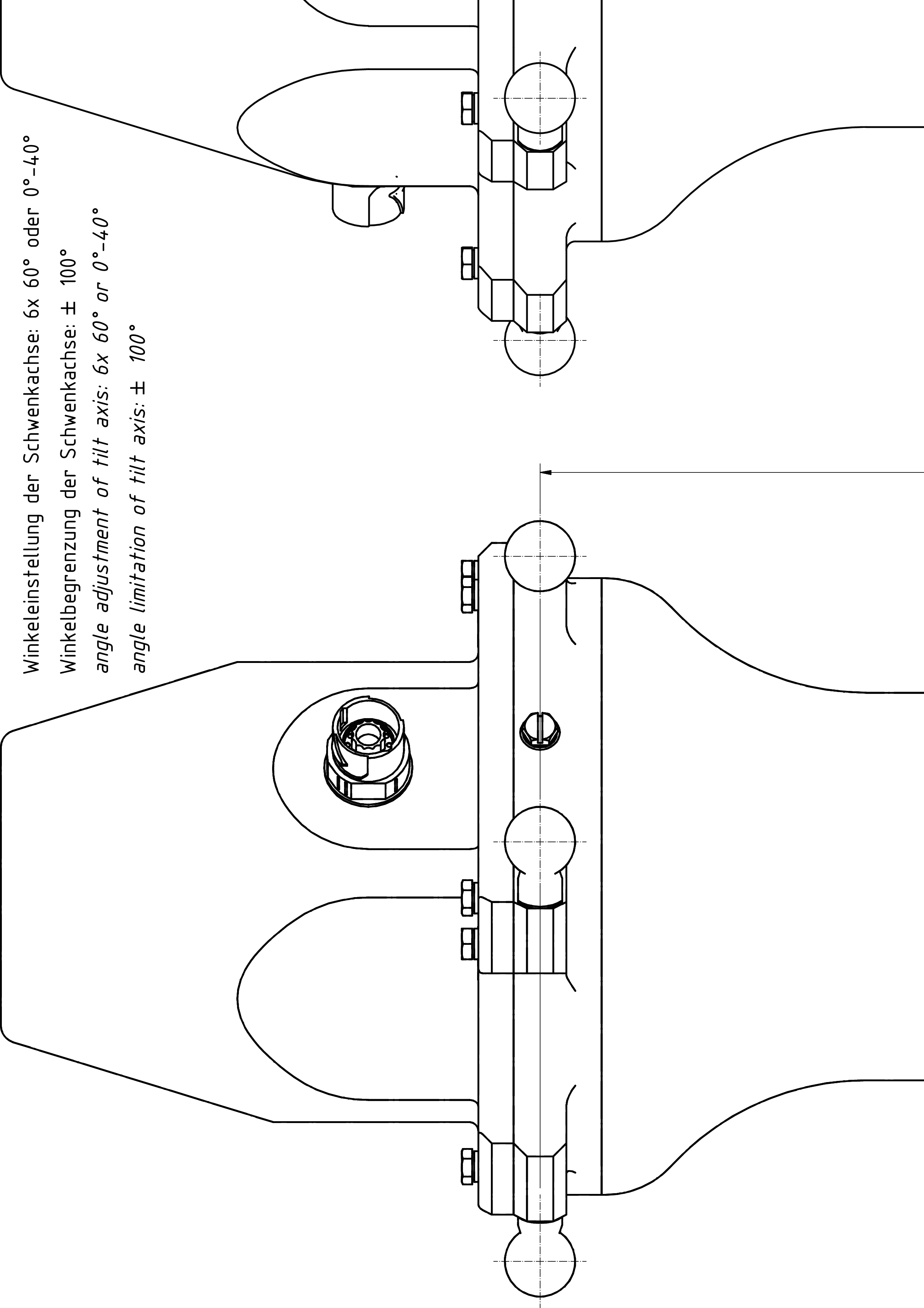

Mounting the Gripper to the Tilting Module HT-B-HD

|

Step |

Action |

|---|---|

|

1 |

Fasten the gripper to the mounting points at the flange (1):

For further information, refer to Flange Dimensions for the Tilting Module HT-B-HD.

|

|

2 |

Calibrate the Tilting Module HT-B-HD if this has not been done before mounting the gripper. For further information, refer to Calibrating the Tilting Module.

NOTE:

|