Safety Logic Controller Memory Key

Presentation

A memory key is required for operation of the Safety Logic Controller, and is sold separately.

The table below presents the reference for the memory key:

|

Reference |

Description |

Color |

|---|---|---|

|

TM5ACSLCM8FS |

Safety Logic Controller memory key, 8 Mb |

Gray and red |

Functions of the Memory Key

The memory key is required to load the program, parameters and configuration into the Safety Logic Controller when it boots up. In addition, you can use the key to store the program, the parameters, and the system configuration and transfer the data to another Safety Logic Controller.

The memory key is equipped with a mechanical locking mechanism to help prevent removal during operation:

|

Locking mechanism |

|

|---|---|

|

Unlocked memory key:

|

Locked memory key:

|

First Insertion and Confirmation of the Memory Key

Before applying power to the Safety Logic Controller for the first time, you have to insert the memory key.

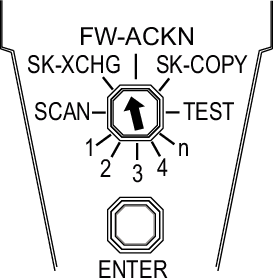

To confirm the first insertion of a memory key, proceed as follows:

|

Step |

Action |

Result |

|---|---|---|

|

1 |

Ensure that the Safety Logic Controller is not under power. |

- |

|

2 |

Insert the memory key in the Safety Logic Controller and apply power to the Safety Logic Controller. |

The FW-ACKN LED illuminates. |

|

3 |

Move the selection switch to SK-XCHG and press the confirmation button. |

The ENTER LED illuminates. The memory key insertion is confirmed. |

|

4 |

Engage the mechanical locking mechanism. |

- |

|

5 |

Open EcoStruxure Machine Expert - Safety, connect to the Safety Logic Controller and set a new password for the Safety Logic Controller (refer to EcoStruxure Machine Expert - Safety User Guide). |

NOTE: To allow the connection between EcoStruxure Machine Expert - Safety and the Safety Logic Controller via the Sercos bus, appropriate Ethernet settings have to be applied on the standard controller. Refer to the M262 Programming Guide, chapter Ethernet Services for information on IP forwarding settings. For PacDrive, refer to the User Guide How to Configure the Firewall for PacDrive LMC Controllers. The CommonToolbox Library Guide provides information on related IEC application functions.

|

|

6 |

Download your valid safety-related application on the Safety Logic Controller (refer to EcoStruxure Machine Expert - Safety User Guide). |

- |

|

7 |

Execute a complete validation of the Safety Logic Controller functional safety system. |

- |

| WARNING | |

|---|---|

Removing a Memory Key

Removing a memory key results in a boot status change and a disabling of the safety-related functions:

-

TM5CSLC100FS / TM5CSLC200FS: The LED indicators F, I and L illuminate.

-

TM5CSLC300FS / TM5CSLC400FS: The LED indicator FS-STATUS illuminates and turns off shortly every second (sequence 900 ms on, and 100 ms off).

In addition, removing the memory key during operation can corrupt the data on the memory key.

| WARNING | |

|---|---|

To remove the memory key, proceed as follows:

|

Step |

Action |

|---|---|

|

1 |

Ensure that the Safety Logic Controller is STOPPED or that power has been removed. |

|

2 |

Disengage the mechanical locking mechanism. |

|

3 |

Pull the memory key out of the Safety Logic Controller.

NOTE: The Safety Logic Controller requires a valid memory key to operate.

|

Copying to a Memory Key

Copying to a memory key is a function that allows you to copy the configuration data from the Safety Logic Controller to another memory key. The application and parameters are not copied to the memory key.

Pre-requisite 1: The Safety Logic Controller is operational, therefore, with an existing memory key.

Pre-requisite 2: You have another memory key, already containing an application valid for the present Safety Logic Controller.

To transfer the configuration data to another memory key, proceed as follows:

|

Step |

Action |

Result/Comment |

|---|---|---|

|

1 |

Set the selection switch to SK-COPY position and press the confirmation button. |

Result: The ENTER LED illuminates and the SKEY LED flashes. The existing memory key configuration data is saved to an internal, temporary file on the Safety Logic Controller to be later transferred to the other memory key, and the FW-ACKN LED flashes when the action is completed. |

|

2 |

Dis-engage the mechanical locking mechanism and replace the existing memory key by the other memory key.(1)

NOTE: Do not move the selection switch. It remains on the position SK-COPY.

|

A maximum of 30-second delay is provided for this step. The FW-ACKN LED flash frequency increases after 20 seconds to signal the end of that delay. |

|

3 |

Press the confirmation button(2). |

The internal, temporarily saved configuration file is transferred to the memory key. |

|

4 |

Move the selection switch to SK-XCHG and press the confirmation button. |

Result: The ENTER LED illuminates. The memory key replacement is confirmed. |

|

5 |

Engage the mechanical locking mechanism. |

- |

|

6 |

Execute a complete validation of the Safety Logic Controller functional safety system. |

- |

|

(1) If no memory key is inserted after 30 seconds, the Safety Logic Controller switches to boot status.

(2) If the other memory key is not acknowledged after 30 seconds, the function ends, that is, in case the function is triggered inadvertently, the copy function ends automatically after 30 seconds. |

||

| WARNING | |

|---|---|

Confirming Memory Key Insertion

The following procedure authorizes the safety-related application stored on the memory key to be used with the Safety Logic Controller. In addition, after confirmation, the application on the memory key is compared with that in execution memory, and if they are different, the application on the memory key is transferred to the Safety Logic Controller.

To confirm the insertion of a memory key, proceed as follows:

|

Step |

Action |

Result |

|---|---|---|

|

1 |

Ensure that the Safety Logic Controller is STOPPED. |

- |

|

2 |

Insert the memory key in the Safety Logic Controller.

NOTE: The Safety Logic Controller requires a valid memory key to operate.

|

The FW-ACKN LED illuminates. |

|

3 |

Move the selection switch to SK-XCHG and press the confirmation button. |

The ENTER LED illuminates. The memory key replacement is confirmed. |

|

4 |

Engage the mechanical locking mechanism. |

- |

|

5 |

Execute a complete validation of the Safety Logic Controller functional safety system. |

- |

| WARNING | |

|---|---|

Use Cases for Copying to a Memory Key

|

Use Case |

Description |

|---|---|

|

Exchange the safety-related application in the controller without using EcoStruxure Machine Expert - Safety |

You can update a safety-related application using a second memory key containing the new application and parameters (for example prepared by Machine Expert - Safety Design Engineer).

|

|

Create a memory key backup with same configuration data without using EcoStruxure Machine Expert - Safety |

The copy function allows you to create a copy or backup of the memory key data.

This memory key backup can then be used in the event the original memory key becomes defective. |

Creating a Memory Key Backup

The procedure described in Copying to a Memory Key can also be used to create a memory key backup by using a second memory key with an identical safety-related application. After executing the procedures, two identical memory keys are available.

Formatting the Memory Key

The following procedure allows you to format the memory key. Only use this procedure if your firmware update was not successful or the memory has a detected error.

A formatting of the memory key deletes the memory key data, including your password.

| NOTICE | |

|---|---|

To format the memory key, proceed as follows:

|

Step |

Action |

Comment / Result |

|---|---|---|

|

1 |

Ensure that the Safety Logic Controller is stopped. |

- |

|

2 |

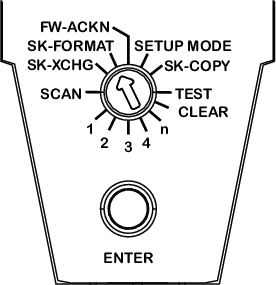

TM5CSLC100FS / TM5CSLC200FS: Move the selection switch to the unlabeled position between SK-XCHG and FW-ACKN. |

|

|

TM5CSLC300FS / TM5CSLC400FS: Move the selection switch to SK-FORMAT. |

|

|

|

3 |

Press the confirmation button for a minimum of 20 s to a maximum of 30 s to receive a confirmation. |

After 20 s, the ENTER LED illuminates.

NOTE:

Result: The LEDs will indicate that there is no valid application on the key |

|

4 |

Follow the procedures necessary to add a valid application to the key. |

- |