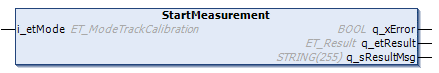

FB_TrackCalibration - StartMeasurement (Method)

Description

With the method StartMeasurement, you can start a measurement run for verifying the calibration of a Lexium™ MC multi carrier track.

Preconditions for the measurement process:

-

Define the working direction of the track (not inverted or inverted) by the parameter Direction in the user function TrackGeometry of the track object . The default value for the parameter Direction is Not inverted / 1. (For more information on the parameter Direction, refer to the Lexium™ MC multi carrier Device Objects and Parameters Guide.)

-

Ensure that there is not more than one carrier without tool and product on the track.

-

Ensure that there are no mechanical obstacles for the carrier on the track.

-

Select the following control loop parameters:

-

i_dwPosP := 500

-

i_dwVelP:= 2000

-

i_dwVelI := 500

-

-

Perform the Init_Track routine of the project Multicarrier Example.

-

Ensure that the carrier and the function block FB_Multicarrier are successfully enabled.

-

Select the track calibration mode in the enumeration ET_ModeTrackCalibration, depending on the working direction of your Lexium™ MC multi carrier track in automatic operation mode.

Measurement process:

By calling the method StartMeasurement, you start the measuring process that runs without further user action. You can verify the status of the process through the property etState (see FB_TrackCalibration).

The measuring process includes the following stages:

-

The carrier moves to the initial position, which is the middle position of the first segment of the track.

-

The measurement is started.

-

The carrier moves around the track from segment to segment until it reaches the initial position.

-

The calibration values are calculated internally.

-

The parameters are not written to the segments.

-

The enumeration ET_StateTrackCalibration displays the status MeasurementSuccessful.

Inputs

|

Input |

Data type |

Description |

|---|---|---|

|

i_etMode |

ET_ModeTrackCalibration |

Access to the enumeration ET_ModeTrackCalibration for selecting the track calibration mode, depending on the working direction of the track in automatic operation mode. |

Outputs

|

Output |

Data type |

Description |

|---|---|---|

|

q_xError |

BOOL |

Indicates TRUE if an error has been detected. For details, refer to q_etResult and q_sResultMsg. |

|

q_etResult |

Provides diagnostic and status information as a numeric value. |

|

|

q_sResultMsg |

STRING [255] |

Provides additional diagnostic and status information as a text message. |