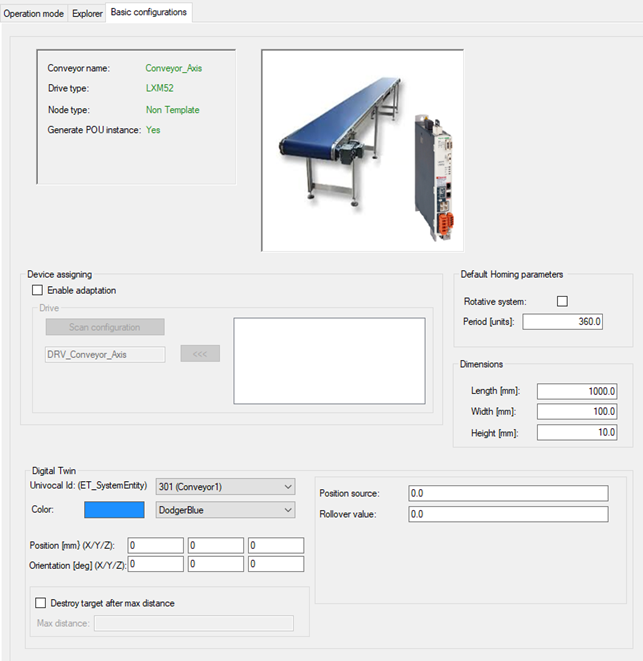

Basic Configurations

Overview

General

|

Element |

Description |

|---|---|

|

Conveyor data |

Displays the data of the selected conveyor. |

|

Graphic |

Displays a graphic of the selected conveyor. |

Device assigning

|

Element |

Description |

|---|---|

|

Device assigning |

Assigns devices to modules. For further information on how to proceed, refer to Device Assigning. |

Default Homing parameters

|

Element |

Description |

|---|---|

|

Rotative system |

The default parameter Rotative system is used for several structure variables.

|

| Period |

The default parameter Period is used for several structure variables.

|

|

|

Configures the dimensions of the conveyor (length, width, height). The dimensions can be read via the method SR_<MyConveyor>.GetDimensions().

NOTE: The parameters for length/width/height are not verified against other parameters, for example stTargets or the position of the conveyor.

|

Digital Twin - Conveyor Module not as submodule of RobotCell

|

Element |

Description |

|---|---|

|

Univocal Id |

Selects a unique ID for the conveyor. Ensure that the Univocal Id is unique for all conveyors used in one project that is connected to a Digital Twin. |

|

Control mode |

Not editable, is set to DTC.ET_ConveyorControlMode.PositioningModuloRollover. |

|

Color |

Selects a color. |

|

Position and Orientation |

Sets the position and orientation to place the conveyor in the Digital Twin. |

|

Position source |

For the position source, you can use the position of a drive or encoder (LE_Encoder.Position) or using an IEC variable of type LREAL. In the case of an IEC variable you must ensure that the variable is updated in time. |

|

Rollover value |

For the rollover value, a value that do not change during execution must be set, therefore either a fix value can be set or an IEC variable of type LREAL. |

|

Destroy target after max distance |

If the checkbox is selected, set a value for the maximum distance in the Digital Twin. |

Digital Twin - Conveyor Module as submodule of RobotCell

|

Element |

Description |

|---|---|

|

Univocal Id |

Selects a unique ID for the conveyor. Ensure that the Univocal Id is unique for all conveyors used in one project that is connected to a Digital Twin. |

|

Control mode |

Not editable, is set to DTC.ET_ConveyorControlMode.PositioningModuloRollover. |

|

Color |

Selects a color. |

|

Position and Orientation |

Sets the position and orientation to place the conveyor in the Digital Twin. |

|

Position source and Rollover value |

For position source and rollover value, you can select between:

|

|

Destroy target after max distance |

If the checkbox is selected, set a value for the maximum distance in the Digital Twin. |