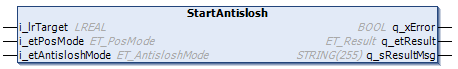

IF_MoveDirectly - StartAntislosh (Method)

Task

Moving the carrier to a target position with an additional antislosh motion profile, without considering other carriers.

Description

When transporting liquids in open bottles or open containers on a Lexium™ MC multi carrier track, liquid could slosh out. To help prevent or reduce the sloshing of homogeneous liquids, you can use the method IF_MoveDirectly - StartAntislosh.

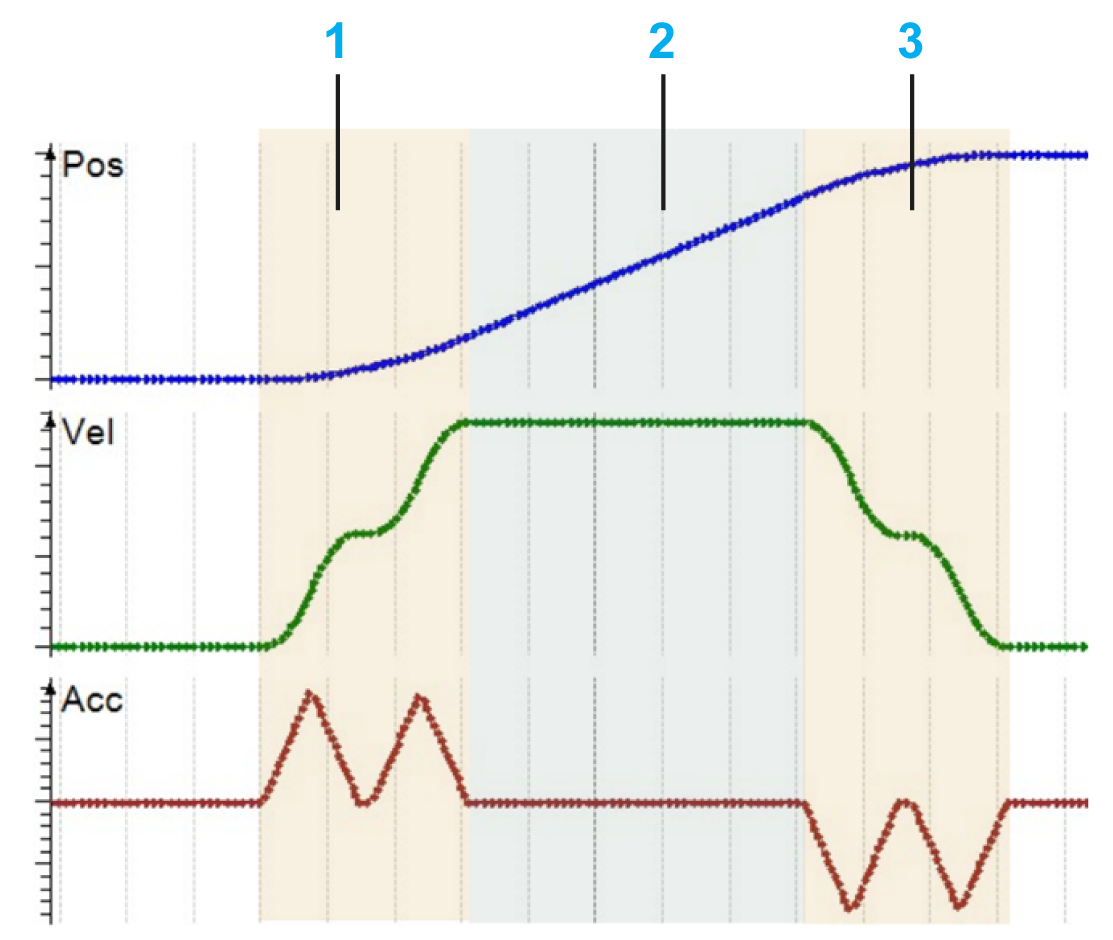

With the method IF_MoveDirectly - StartAntislosh, the carrier is moved to a given target position without considering other carriers, similarly to the method IF_MoveDirectly - Start. Additionally, an antislosh motion profile helps to flatten the wave profile of the transported liquid. For the internal calculation of the antislosh motion profile, the natural damping coefficient and the natural frequency of the liquid, specified with the method IF_CarrierConfiguration - SetAntisloshParameter, are taken into account.

1 Acceleration phase

2 Velocity phase

3 Deceleration phase

With an open track, the carriers could leave the track at the ends. Therefore, mechanical hard stops must be mounted at both ends of an open track.

| WARNING | |

|---|---|

Inputs

|

Input |

Data type |

Value range |

Unit |

Description |

|---|---|---|---|---|

|

i_lrTarget |

LREAL |

0.0 ≤ i_lrTarget ≤ lrTrackLength (1) |

mm |

Specifies the distance to the end target. The travel distance to the target depends on the positioning mode defined by the parameter i_etPosMode. |

|

i_etPosMode |

ET_PosMode |

– |

– |

For the positioning modes available, refer to the enumeration ET_PosMode. |

|

i_etAntisloshMode |

ET_AntisloshMode |

– |

– |

For the antislosh modes Standard and Advanced, refer to the enumeration ET_AntisloshMode. |

|

(1) In the positioning modes Relative and Absolute, i_lrTarget is not limited to the track length as specified by the parameter lrTrackLength when the track in question is a closed track. For more information on the track length, refer to lrTrackLength. |

||||

Outputs

|

Output |

Data type |

Description |

|---|---|---|

|

q_xError |

BOOL |

Indicates TRUE if an error has been detected. For details, refer to q_etResult and q_sResultMsg. |

|

q_etResult |

Provides diagnostic and status information as a numeric value. |

|

|

q_sResultMsg |

STRING [255] |

Provides additional diagnostic and status information as a text message. |

Call Examples

Before executing the method IF_MoveDirectly - StartAntislosh, the method IF_CarrierConfiguration - SetAntisloshParameter and the method IF_Motion – SetMotionParameter must be called at least once.

Example 1:

...ifConfiguration.SetAntisloshParameter(...)

...ifMotion.SetMotionParameter(...)

...ifMoveDirectly.StartAntislosh(...)Example 2:

...ifConfiguration.SetAntisloshParameter(...)

...ifMotion.SetMotionParameter(...)

...ifMoveDirectly.StartAntislosh(...)

...ifMoveDirectly.StartAntislosh(...)