Auto-Tuning (Heating) - FB_HeatingControl2

Start Auto-tuning

The set point is the only parameter which is required for auto-tuning. The set point has to be given to input i_rSetPoint. Start auto-tuning through the pin i_xAutoTune. Enter the set point at input i_rSetPoint. The set point has to be at least 10 °C greater than the present process value. If the temperature difference between the set point and the process value is less than 10 °C, auto-tuning waits until this start condition is fulfilled.

The heating is switched to 100%. The settings i_stTemperatureControl.rPidHighLimit and i_stTemperatureControl.rPidLowLimit are not taken into account during auto-tuning. The system is heated up to near the set point. The switch-off point of the heating depends on the set temperature, the system delay time and the maximum rate of temperature rise. After the process value (temperature) has cooled down below the set point, the P and I parameters are determined and the auto-tuning is finished. The PID parameters rKp and rTn are calculated automatically. A Differentiation (D) component rTv is not calculated as it can make the control loop unstable. If a D component is required, for example, to improve reaction to disturbance variables, determine and configure it manually. The calculated PI parameters are given to the array structure element iq_stParameterSetsPID.

Also refer to FB_HeatingControl2.

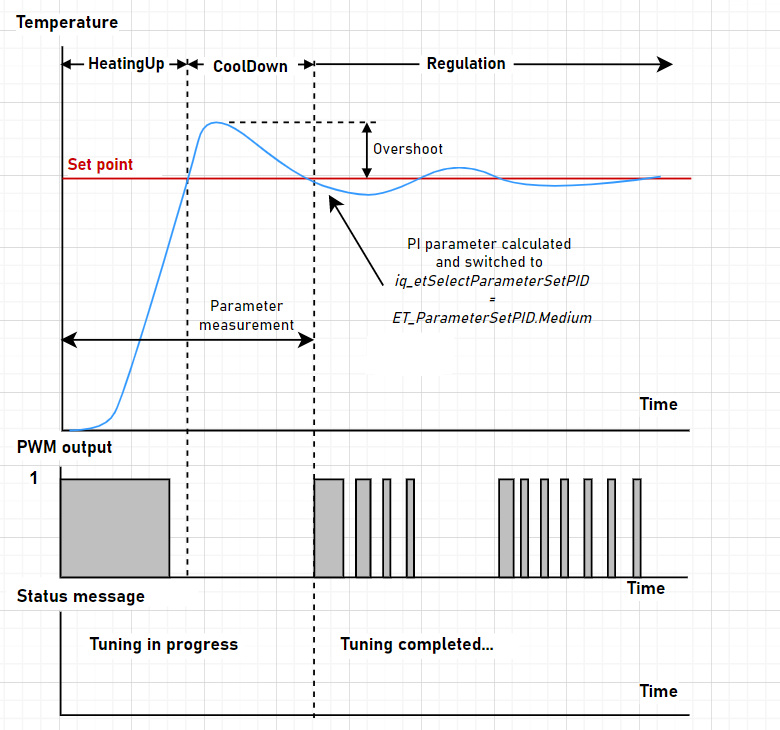

Status messages are provided to function block outputs (q_xAutoTuneActive and q_etStatusAutoTune) to inform about auto-tuning.

To achieve acceptable auto-tuning results, run auto-tuning while the machine is not in production or automatic mode.

Exemplary Sequence of Auto-tuning

After the cooling down phase, the three PID parameter sets are calculated and iq_etSelectParameterSetPID is automatically set to ET_ParameterSetPID.Medium.

System Comparison After Auto-tuning

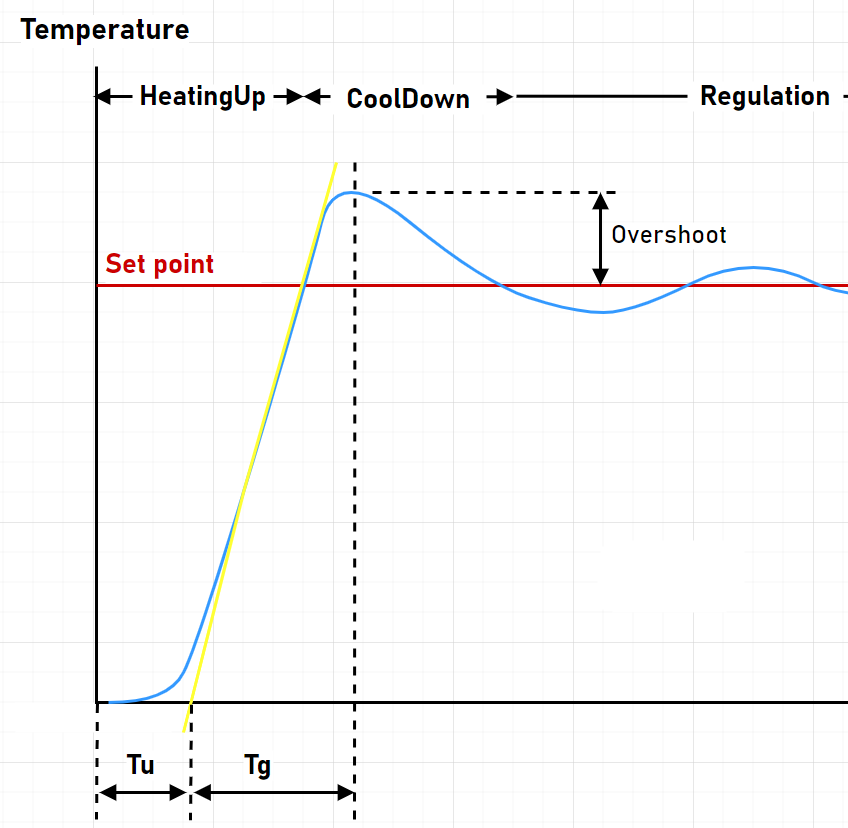

The P and I parameters calculation is mainly based on the reversed tangent method and the two system-relevant parameters:

-

system delay time Tu

-

system compensation time Tg

The ratio of Tg to Tu determines the controllability of the complete system.

The following applies:

|

Ratio of Tg to Tu |

Controllability |

|---|---|

|

<3 |

Poorly managable. Control and design measures are required. |

|

3...10 |

Moderately managable. |

|

>10 |

Well managable. |