The implementation of physics engine in Machine Expert Twin can present some limitations in specific scenarios such as where a component moves from point A to point B at high speeds and the collision with a sensor is not triggered.

Every ≈16ms (T=1/60Hz) the Physics engine performs a step where the position of dynamic rigid parts (loads) is calculated based on the forces applied to them caused either by collision with other dynamic/rigid parts or speed applied by a conveyor. On the other hand, the Physics engine calls the Step method of each assembly contained in the Assemblies list every time the engine advances the time.

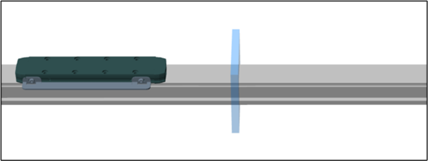

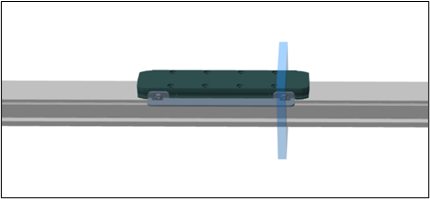

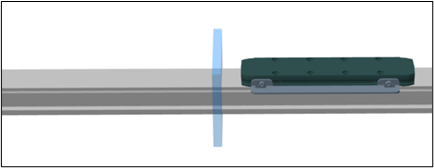

Due to this fact, sensors will be able to detect a collision with a rigid part every ≈16ms. In case a rigid part is moving at high speeds, the collision could not be triggered as a consequence of the high value presented in the displacement from point to point as the following images show where the speed used in case A is minor than case B.

In the example presented above, the position of the carriage is given by the value received from the PLC which is updated every ≈10ms and has large values of displacement between steps, generating inconsistent detections of the carriage by the sensor.

To solve this problem, the position of the carriage will be updated in the scene every ≈10ms by using the event OnReceived coming from the Input class. Furthermore, the detection of the carriage by a sensor will be simulated not by a physical sensor but using a mathematical expression which will define if the carriage is in a certain range. This task is carried in the same method subscribed to the event OnReceived.