Tools required:

o5 mm (0.197 in) hex key

o10 mm (0.39 in) socket

o7 mm (0.276 in) open wrench

oTorque wrench

oOil

Tools suggested:

oSyringe and tube

|

|

|

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH |

|

oDisconnect all power from all equipment including connected devices prior to removing any covers or doors, or installing or removing any accessories, hardware, cables, or wires. oPlace a "Do Not Turn On" or equivalent hazard label on all power switches and lock them in the non-energized position. oWait 15 minutes to allow the residual energy of the DC bus capacitors to discharge. oMeasure the voltage on the DC bus with a properly rated voltage sensing device and verify that the voltage is less than 42.4 Vdc. oDo not assume that the DC bus is voltage-free when the DC bus LED is off. oBlock the motor shaft to prevent rotation prior to performing any type of work on the drive system. oDo not create a short-circuit across the DC bus terminals or the DC bus capacitors. oReplace and secure all covers, accessories, hardware, cables, and wires and confirm that a proper ground connection exists before applying power to the unit. oUse only the specified voltage when operating this equipment and any associated products. |

|

Failure to follow these instructions will result in death or serious injury. |

Initial position:

oRemove the ring holding the mechanical limit stops on axis 1 (if installed).

|

Step |

Action |

|---|---|

|

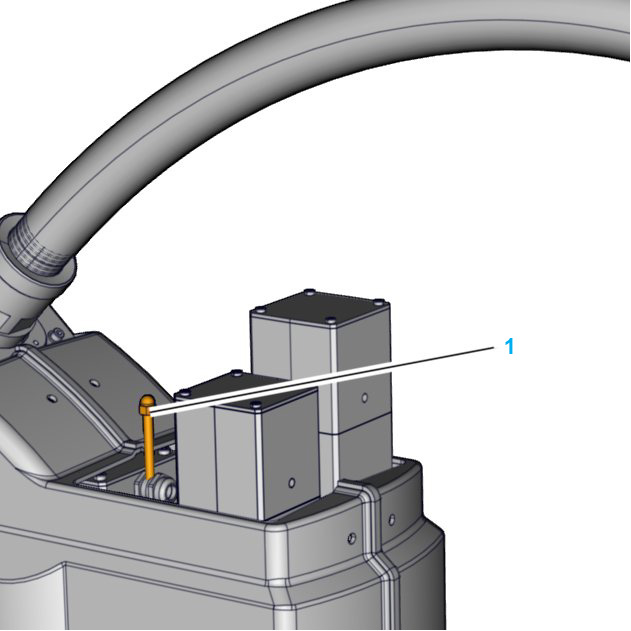

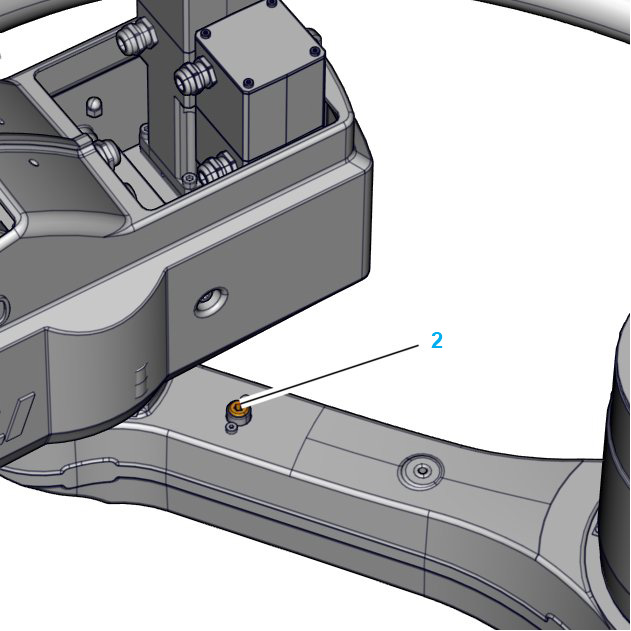

1 |

Loosen the breather (1).

|

|

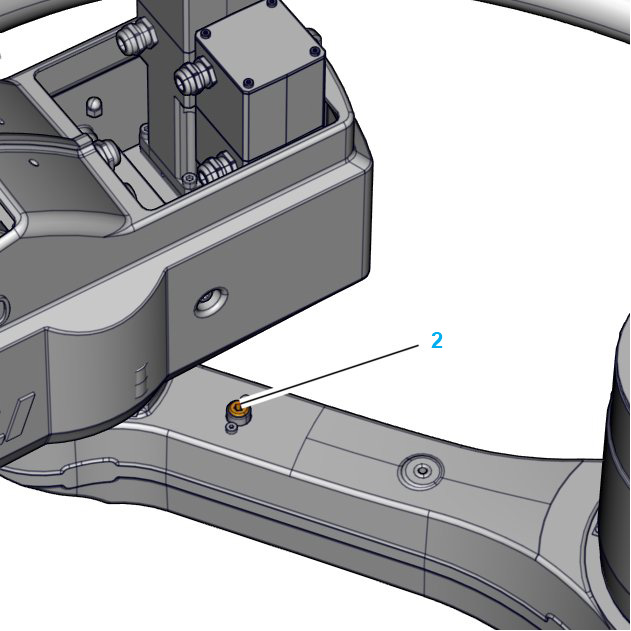

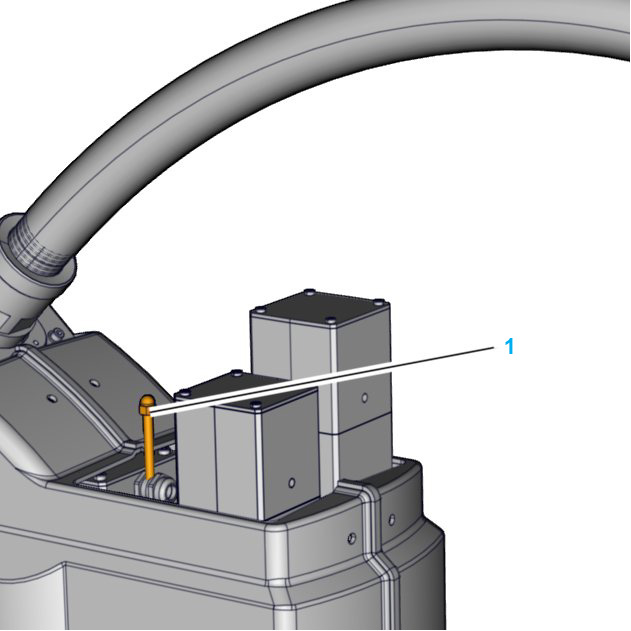

2 |

Remove the plug (2).

|

|

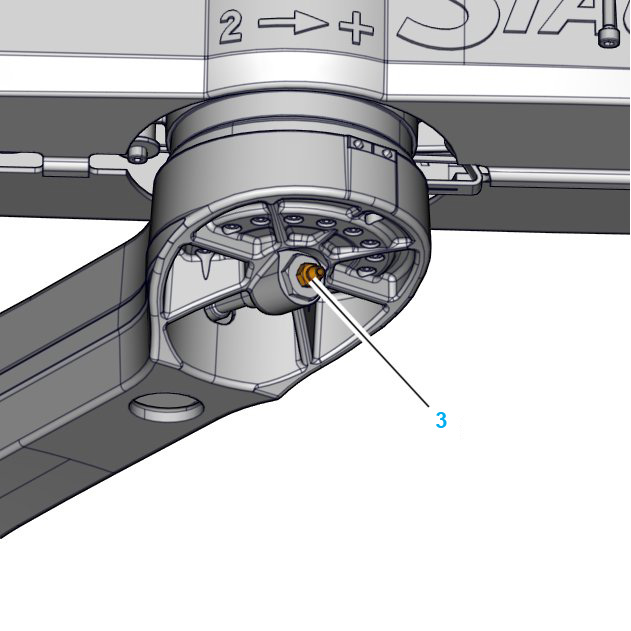

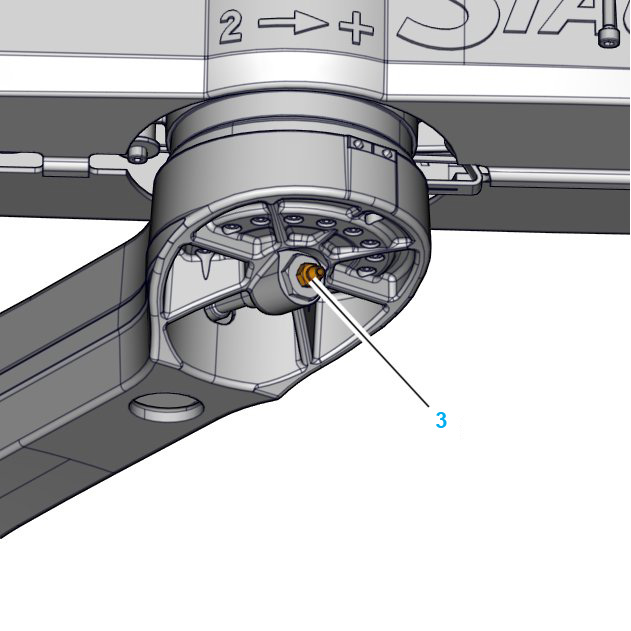

3 |

Partially unscrew the drain screw (3).

|

|

4 |

Suck out the used oil. |

|

5 |

Inject new oil until the oil level reaches the middle of the groove (4).

|

|

6 |

Tighten the drain screw (3) to a torque level of 6 Nm (53 Nm).

|

|

7 |

Screw the plug (2) back in and tighten to a torque of 5 Nm (44 lbf-in).

|

|

8 |

Tighten the breather (1).

|

|

9 |

Verify the oil level of axis 2 again after a few rotations of the gearbox. For further information, refer to Verifying the Oil Level of Axis 2. |