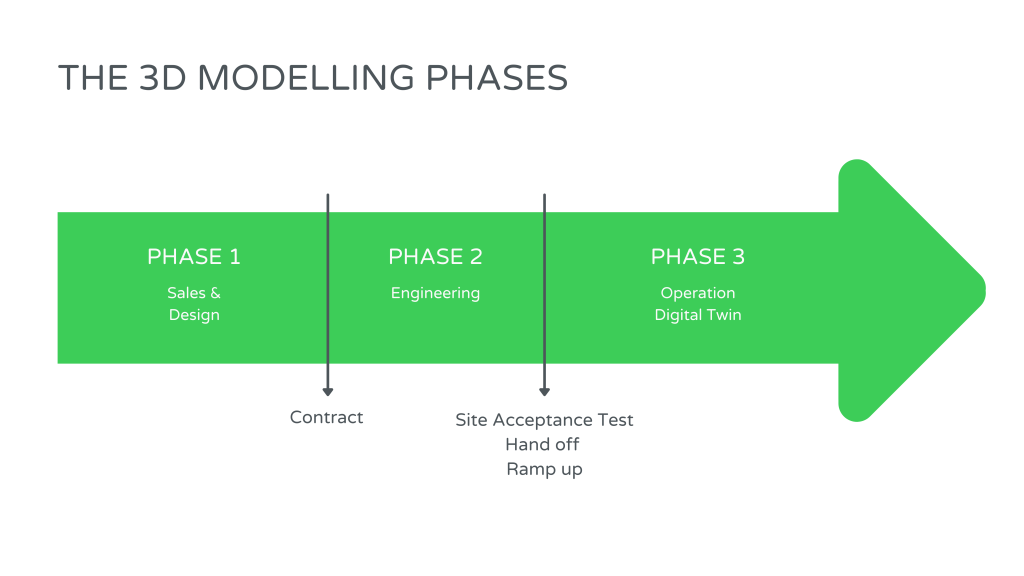

A 3D model can be useful in all three main phases of a system:

The modelling objectives differ within the three main phases of a system:

- Product or systems development

- Execution – engineering, virtual commissioning, and commissioning

- Operation

Product or Systems Development

A digital model of a planned assembly line can be useful for many different things including:

Visualization – telling the story and showing the functionality

A model can be part of the storytelling process around a new project. It makes it possible to show what the future system will look like and how it will function. This can be helpful for both intern and extern communication as employees will be able to visualize the end goal and know what they are working towards and the sales department will be able to show customers the future product in detail.

Support concurrent development – facilitate integrated engineering

Classic simulation for decision support

A digital model of the future system can be very useful when it comes to making important decisions surrounding the project. It will allow you to see how the machinery will function under different circumstances so you can make the optimal decisions based on actual knowledge rather than just best guesses.

Execution – Engineering, Virtual commissioning and Commissioning

System documentation for mechanics, OT, and IT

Virtual Commissioning – OT testing, IT testing, OT-IT-testing

- Software development audits (SDA)

- Test scenarios for bug fixing, normal run, error handling, recovery, contingency actions, stress/load testing, verification of capacity (design criteria)

- vFATs

Operation

After the physical assembly line is up and running, the digital model still has many useful functions including:

Training Simulator – reuse the VC setup with HMI, UI, control(s) for high-end off-line training

Test patches, upgrades, and new releases off-line before upload to production

A digital model enables you to test any changes you wish to make on the assembly line in the digital version first. This means that you can test different scenarios without ever interfering with the physical assembly line. That way, you can work out any bugs in upgrades before you make them live.

Digital Twinning – level 2 – remote live visualization