Using the library with other versions of software or firmware may have results other than described in the present documentation.

|

|

|

UNINTENDED EQUIPMENT OPERATION |

|

oBe sure that the software and firmware are of the versions supported by this library. oContact your Schneider Electric service representative for compatibility information. |

|

Failure to follow these instructions can result in death, serious injury, or equipment damage. |

oPacDrive LMC Eco

oPacDrive LMC Pro

oPacDrive LMC Pro2

oSoMachine Motion V4.3 SP1

PacDrive 3 V4.3 SP1

oPacDrive LMC Eco V1.54.20.3 or greater

oPacDrive LMC Pro V1.54.20.3 or greater

oPacDrive LMC Pro2 V1.54.20.3 or greater

oLinear Tracking System

oIF_RobotConfiguration.AddLinearTrackingSystem3(…)

By using this method to configure a linear tracking system, it is possible to define the system ID.

oAdditional Transformation TCP

oIF_RobotConfigurationAdvanced.AdditionalTransformationTCP(…)

An additional user-defined transformation for the TCP can be configured.

oResulting Acceleration Limitation Parameters

oIF_RobotConfigurationAdvanced.SetResAccLimitParameters(…)

Additional configuration parameters for the functionality to limit the resulting acceleration of a robot space movement can be set.

oIF_RobotConfigurationAdvanced.GetResAccLimitParameters(…)

Additional configuration parameters for the functionality to limit the resulting acceleration of a robot space movement can be read.

oEstimated Stop Position AuxAx

oIF_RobotFeedbackMotionAuxiliaryAxis.lrEstimatedStopPosition

Returns the estimated stop position of an active movement of an auxiliary axis.

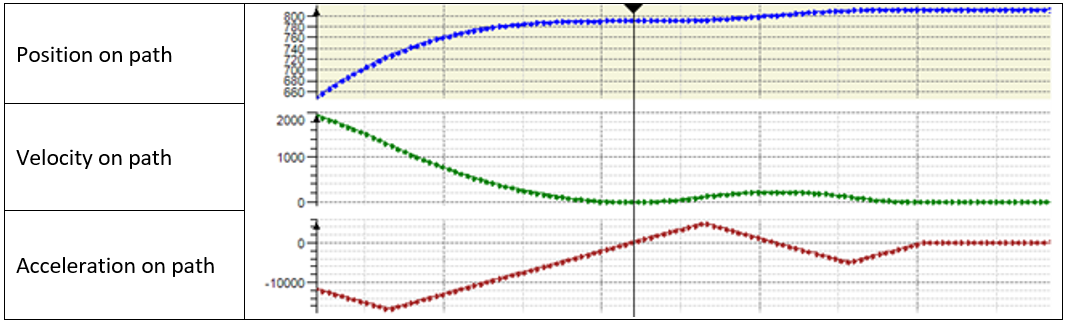

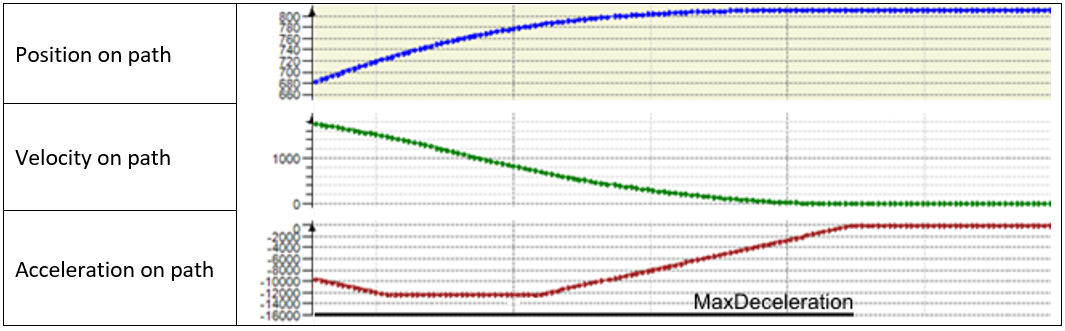

oTarget Extension of a Connected Path

In several situations, the velocity of the path movement gets zero during the movement.

Situations:

a.The path movement of the robot is in the deceleration phase to its end position. A motion command IF_RobotMotion.MoveL(…), IF_RobotMotion.MoveC(…), or IF_RobotMotion.MoveS(…) is sent to extend the path movement of the robot.

b.A IF_RobotMotion.SetStopOnPath(…) command is active and the path movement of the robot is in the deceleration phase to the stop position on path. The stop-on-path is reset by the IF_RobotMotion.ResetStopOnPath(…) command.

c.The parameter IF_RobotMotion.lrVelOverride was set to 0.0 and the path movement of the robot is in the deceleration phase to stop-on-path. The parameter IF_RobotMotion.lrVelOverride is set to a value greater than 0.0.

d.FB_Robot.xStart was set to FALSE and the path movement of the robot is in the deceleration phase to stop-on-path. FB_Robot.xStart is set to TRUE again.

If it is possible, a motion profile is calculated without zero velocity during the path movement.

oLicense Points

License points are no longer required by the following functions:

oIF_RobotConfiguration.Delta2Ax

oIF_RobotConfiguration.Delta3Ax

oIF_RobotConfiguration.Articulated2Ax

oIF_RobotConfiguration.SchneiderElectricRobot

oTransform Coordinate

The Application Logger entry of a successful call of the method IF_RobotMotion.TransformCoordinate(…) is removed.

oCalculating the Estimated Stop Position

oUnder certain conditions, the diagnostic message ET_Diag.UnexpectedProgramBehavior was returned by the robot during calculating the estimated stop position of the TCP on the connected path.

Calculating the estimated stop position is improved.

oCalculating a Motion Profile

oUnder certain conditions, the diagnostic message ET_Diag.UnexpectedProgramBehavior was returned by a move command (MoveL, MoveS, MoveC) in connection with calculating the motion profile of the connected path.

oUnder certain conditions, the diagnostic message ET_Diag.ExecutionAborted - ET_DiagExt.SwitchTimeInvalid was returned by the robot.

oUnder certain conditions, the diagnostic message ET_Diag.ExecutionAborted - ET_DiagExt.PathPositionEndExceeded was returned by the robot.

Calculating the motion profile is improved.

oSoftware Watchdog Caused by Calculating Spline Points

oFB_EllipticSpline.CalcSplineExtended(…)

Calling this method could lead into a software watchdog.

Calculating spline points is improved.

oHardware Watchdog Caused by Enabling the Robot

oFB_Robot.xEnable TRUE -> FALSE

Enabling the robot could lead into a hardware watchdog.

Enabling the robot is improved.

oTarget Position of Connected Path Not Reached

oUnder certain conditions, the target position of a connected path has not been reached.

IF_RobotFeedback.xInMotion returns FALSE, but IF_RobotFeedback.xInTarget returns not TRUE.

Reaching the target position of a connected path is improved.

oStop on Path

oIF_RobotMotion.SetStopOnPath(…)

The method can be called successfully even if IF_RobotMotion.lrVelOverride was set to 0.0.

Calling the method is improved.

oCalculating an Elliptic Spline

FB_EllipticSpline.CalcFullSpline(…)

The method returns the correct spline points even if a working plane is configured and the method is called more than once without any change of the input parameters.

Calculating an elliptic spline is improved.

oSercos Write Cycle Overflow

FB_Robot.xEnable TRUE -> FALSE

Under certain conditions, the diagnostic message 8507 Sercos write cycle overflow was caused by disabling the robot.

Disabling the robot is improved.